- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

blog

Prismatic cell production

- 2024-07-02

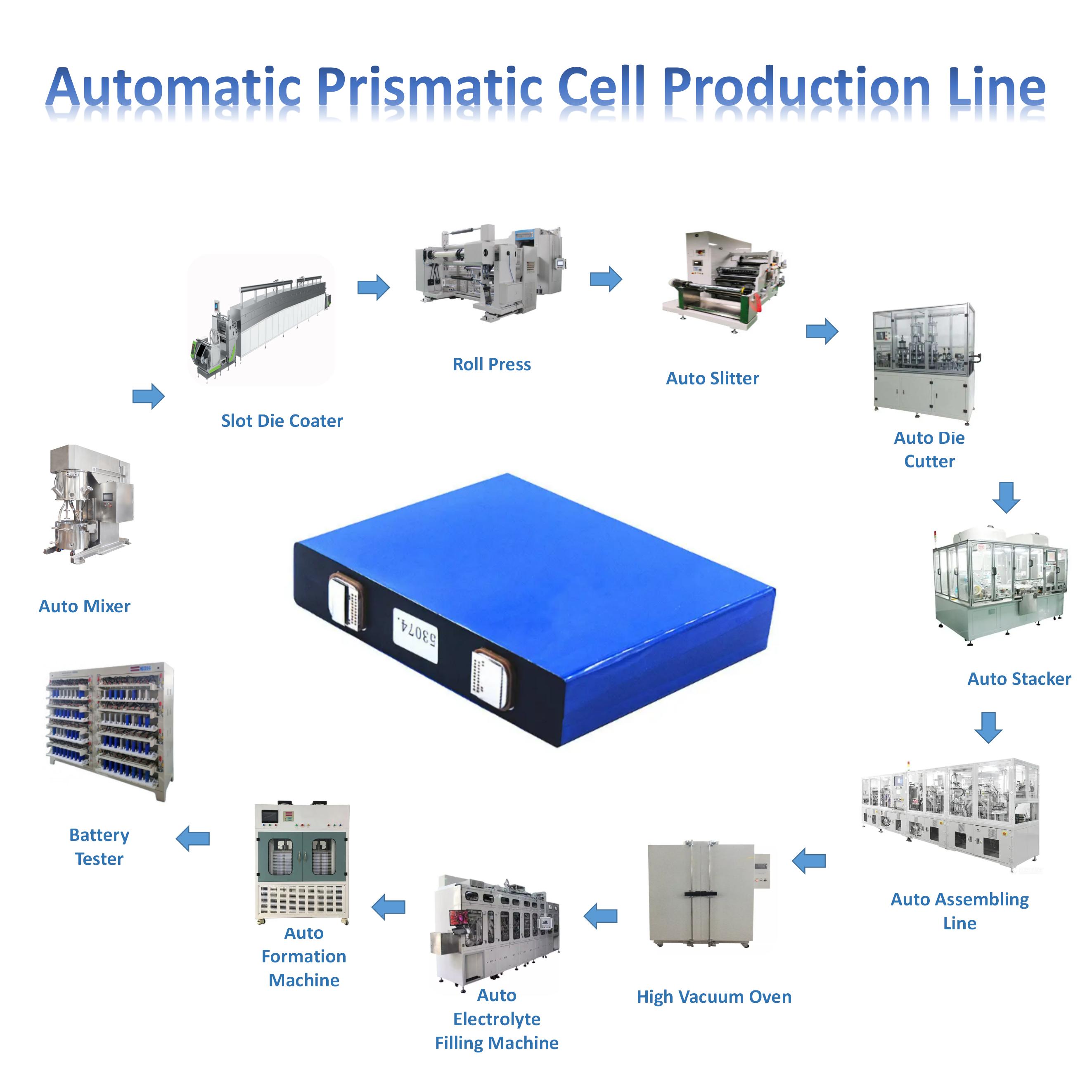

Prismatic Cell Production: A Comprehensive Guide

Prismatic cells are a type of lithium-ion battery cell that offers a compact and efficient design, making them suitable for a variety of applications, including electric vehicles, consumer electronics, and energy storage systems. This guide provides a detailed overview of the prismatic cell production process, key components, equipment used, advantages, and challenges.

Key Components of Prismatic Cells

Cathode: Typically made from lithium metal oxides such as lithium cobalt oxide (LiCoO2), lithium iron phosphate (LiFePO4), or nickel manganese cobalt oxide (NMC).

Anode: Usually composed of graphite or other carbon materials.

Electrolyte: A lithium salt (e.g., LiPF6) dissolved in an organic solvent.

Separator: A thin, porous polymer membrane that prevents short-circuiting by keeping the cathode and anode apart while allowing ion flow.

Current Collectors: Conductive materials like aluminum (for the cathode) and copper (for the anode) that collect and transfer electrons.

Housing: Typically a metallic casing that encloses the cell components and provides structural integrity.

Steps in Prismatic Cell Production

1. Electrode Preparation

Mixing: Active materials, conductive additives, and binders are mixed with a solvent to form a slurry.

Coating: The slurry is applied to the current collector foils using an electrode coater.

Drying: The coated electrodes are dried to remove the solvent, leaving a solid layer of active material.

Calendering: The dried electrodes are compressed using calendering rollers to achieve the desired thickness and density.

Cutting: The electrodes are cut into precise shapes and sizes suitable for the cell design.

2. Assembly

Stacking or Winding: The prepared electrodes and separators are either stacked or wound together to form the electrode assembly.

Tab Welding: Tabs (current collectors) are welded onto the electrodes to facilitate electrical connections.

Insertion into Housing: The electrode assembly is inserted into the prismatic cell housing.

Electrolyte Filling: The electrolyte is injected into the cell, ensuring complete wetting of the electrodes.

Sealing: The cell is sealed using techniques like laser welding to ensure it is airtight and leak-proof.

3. Formation and Aging

Formation Cycling: The cells undergo initial charge-discharge cycles to form a stable SEI (Solid Electrolyte Interphase) layer on the anode and stabilize electrochemical properties.

Aging: The cells are stored under controlled conditions for a period to ensure performance stability.

4. Testing and Quality Control

Electrical Testing: Cells are tested for voltage, capacity, internal resistance, and other key parameters.

Leak Testing: Cells are inspected for electrolyte leakage and housing integrity.

Safety Testing: Cells undergo various safety tests, including short-circuit, overcharge, and thermal stability tests.

Equipment Used in Prismatic Cell Production

Mixers: For preparing electrode slurries.

Coating Machines: To apply the slurry onto current collector foils.

Drying Ovens: For removing solvents from coated electrodes.

Calendering Machines: To compress the electrodes to the desired thickness and density.

Cutting Machines: For precision cutting of electrodes.

Stacking/Winding Machines: For assembling the electrodes and separators.

Welding Machines: For tab welding and sealing the cell housing.

Electrolyte Filling Machines: To dispense electrolyte into the cells.

Formation Equipment: For initial charging and cycling of the cells.

Testing Equipment: For electrical, leak, and safety testing.

Advantages of Prismatic Cells

High Energy Density: Efficient use of space within the cell housing allows for high energy storage capacity.

Design Flexibility: The rectangular shape makes them easy to stack and fit into various device designs.

Robust Structure: The rigid housing provides good mechanical stability and durability.

Thermal Management: The flat design aids in better heat dissipation compared to cylindrical cells.

Challenges in Prismatic Cell Production

Manufacturing Complexity: The assembly process is more complex and precise compared to cylindrical cells.

Cost: Higher production costs due to the complexity of manufacturing and materials used.

Quality Control: Ensuring consistent quality across large production batches requires rigorous testing and control measures.

Mechanical Stress: Prismatic cells can be more susceptible to mechanical damage during assembly and use due to their rigid structure.

Development Challenges

Material Innovations: Developing new materials that offer higher energy densities, longer cycle life, and better safety profiles.

Process Optimization: Improving manufacturing processes to enhance efficiency and reduce costs.

Scalability: Scaling up production to meet the growing demand for prismatic cells, especially in electric vehicles and energy storage systems.

Environmental Impact: Addressing the environmental concerns related to the production and disposal of lithium-ion cells.

Conclusion

Prismatic cell production involves a complex and precise process that ensures high performance, safety, and reliability. The advantages of prismatic cells, such as high energy density, design flexibility, and robust structure, make them ideal for a wide range of applications. However, the challenges associated with manufacturing complexity, cost, and quality control require ongoing research and development efforts to improve production processes and material performance. As advancements continue, prismatic cells are poised to play a crucial role in the future of energy storage and power supply technologies.

Prismatic cells are a type of lithium-ion battery cell that offers a compact and efficient design, making them suitable for a variety of applications, including electric vehicles, consumer electronics, and energy storage systems. This guide provides a detailed overview of the prismatic cell production process, key components, equipment used, advantages, and challenges.

Key Components of Prismatic Cells

Cathode: Typically made from lithium metal oxides such as lithium cobalt oxide (LiCoO2), lithium iron phosphate (LiFePO4), or nickel manganese cobalt oxide (NMC).

Anode: Usually composed of graphite or other carbon materials.

Electrolyte: A lithium salt (e.g., LiPF6) dissolved in an organic solvent.

Separator: A thin, porous polymer membrane that prevents short-circuiting by keeping the cathode and anode apart while allowing ion flow.

Current Collectors: Conductive materials like aluminum (for the cathode) and copper (for the anode) that collect and transfer electrons.

Housing: Typically a metallic casing that encloses the cell components and provides structural integrity.

Steps in Prismatic Cell Production

1. Electrode Preparation

Mixing: Active materials, conductive additives, and binders are mixed with a solvent to form a slurry.

Coating: The slurry is applied to the current collector foils using an electrode coater.

Drying: The coated electrodes are dried to remove the solvent, leaving a solid layer of active material.

Calendering: The dried electrodes are compressed using calendering rollers to achieve the desired thickness and density.

Cutting: The electrodes are cut into precise shapes and sizes suitable for the cell design.

2. Assembly

Stacking or Winding: The prepared electrodes and separators are either stacked or wound together to form the electrode assembly.

Tab Welding: Tabs (current collectors) are welded onto the electrodes to facilitate electrical connections.

Insertion into Housing: The electrode assembly is inserted into the prismatic cell housing.

Electrolyte Filling: The electrolyte is injected into the cell, ensuring complete wetting of the electrodes.

Sealing: The cell is sealed using techniques like laser welding to ensure it is airtight and leak-proof.

3. Formation and Aging

Formation Cycling: The cells undergo initial charge-discharge cycles to form a stable SEI (Solid Electrolyte Interphase) layer on the anode and stabilize electrochemical properties.

Aging: The cells are stored under controlled conditions for a period to ensure performance stability.

4. Testing and Quality Control

Electrical Testing: Cells are tested for voltage, capacity, internal resistance, and other key parameters.

Leak Testing: Cells are inspected for electrolyte leakage and housing integrity.

Safety Testing: Cells undergo various safety tests, including short-circuit, overcharge, and thermal stability tests.

Equipment Used in Prismatic Cell Production

Mixers: For preparing electrode slurries.

Coating Machines: To apply the slurry onto current collector foils.

Drying Ovens: For removing solvents from coated electrodes.

Calendering Machines: To compress the electrodes to the desired thickness and density.

Cutting Machines: For precision cutting of electrodes.

Stacking/Winding Machines: For assembling the electrodes and separators.

Welding Machines: For tab welding and sealing the cell housing.

Electrolyte Filling Machines: To dispense electrolyte into the cells.

Formation Equipment: For initial charging and cycling of the cells.

Testing Equipment: For electrical, leak, and safety testing.

Advantages of Prismatic Cells

High Energy Density: Efficient use of space within the cell housing allows for high energy storage capacity.

Design Flexibility: The rectangular shape makes them easy to stack and fit into various device designs.

Robust Structure: The rigid housing provides good mechanical stability and durability.

Thermal Management: The flat design aids in better heat dissipation compared to cylindrical cells.

Challenges in Prismatic Cell Production

Manufacturing Complexity: The assembly process is more complex and precise compared to cylindrical cells.

Cost: Higher production costs due to the complexity of manufacturing and materials used.

Quality Control: Ensuring consistent quality across large production batches requires rigorous testing and control measures.

Mechanical Stress: Prismatic cells can be more susceptible to mechanical damage during assembly and use due to their rigid structure.

Development Challenges

Material Innovations: Developing new materials that offer higher energy densities, longer cycle life, and better safety profiles.

Process Optimization: Improving manufacturing processes to enhance efficiency and reduce costs.

Scalability: Scaling up production to meet the growing demand for prismatic cells, especially in electric vehicles and energy storage systems.

Environmental Impact: Addressing the environmental concerns related to the production and disposal of lithium-ion cells.

Conclusion

Prismatic cell production involves a complex and precise process that ensures high performance, safety, and reliability. The advantages of prismatic cells, such as high energy density, design flexibility, and robust structure, make them ideal for a wide range of applications. However, the challenges associated with manufacturing complexity, cost, and quality control require ongoing research and development efforts to improve production processes and material performance. As advancements continue, prismatic cells are poised to play a crucial role in the future of energy storage and power supply technologies.

HOT PRODUCTS

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915