- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- 2024-01-12

Prismatic cell pilot plants are facilities designed for the testing and development of prismatic (rectangular) lithium-ion battery cells at a smaller scale before full-scale production. These pilot plants play a crucial role in evaluating the feasibility, performance, and scalability of prismatic cell designs. Here are some common applications of prismatic cell pilot plants:

Research and Development:

Cell Design Optimization: Pilot plants allow researchers and engineers to optimize the design of prismatic cells, including electrode materials, electrolytes, and overall cell architecture.

New Technologies: Researchers can test and implement new technologies, such as advanced materials or manufacturing processes, on a smaller scale before full-scale production.

Performance Testing:

Cycle Life Testing: Pilot plants enable the evaluation of prismatic cell cycle life under different charging and discharging conditions, providing insights into long-term performance.

Rate Capability: Testing at various charge and discharge rates helps assess the rate capability of prismatic cells, critical for applications with high power demands.

Safety Testing:

Thermal Management: Pilot plants allow for the study of thermal management strategies to ensure the safety of prismatic cells under different operating conditions.

Abuse Testing: Researchers can simulate and study potential abuse scenarios, such as overcharging or overheating, to improve the safety features of prismatic cells.

Scale-up Studies:

Scalability Assessment: Pilot plants serve as a platform to assess the scalability of prismatic cell manufacturing processes before transitioning to larger production facilities.

Production Cost Analysis: Researchers can analyze production costs and identify potential areas for cost reduction in prismatic cell manufacturing.

Quality Control:

Consistency Testing: Pilot plants help establish and maintain consistent production processes to ensure the quality and reliability of prismatic cells.

Material Characterization: Researchers can conduct detailed material characterization to identify and address any variations that may impact cell performance.

Market Testing:

Prototype Production: Pilot plants allow for the production of small batches of prismatic cells for market testing and evaluation by potential customers.

Customer Feedback: Feedback from early users and customers can be collected to refine the design and address any issues before full-scale production.

Customized Cell Development:

Tailored Solutions: Pilot plants enable the development of prismatic cells tailored to specific applications, such as electric vehicles, grid storage, or consumer electronics.

Prismatic cell production plant are an essential step in the development and commercialization of prismatic lithium-ion batteries. They provide a controlled environment for testing, refining, and validating new technologies and manufacturing processes before committing to large-scale production.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

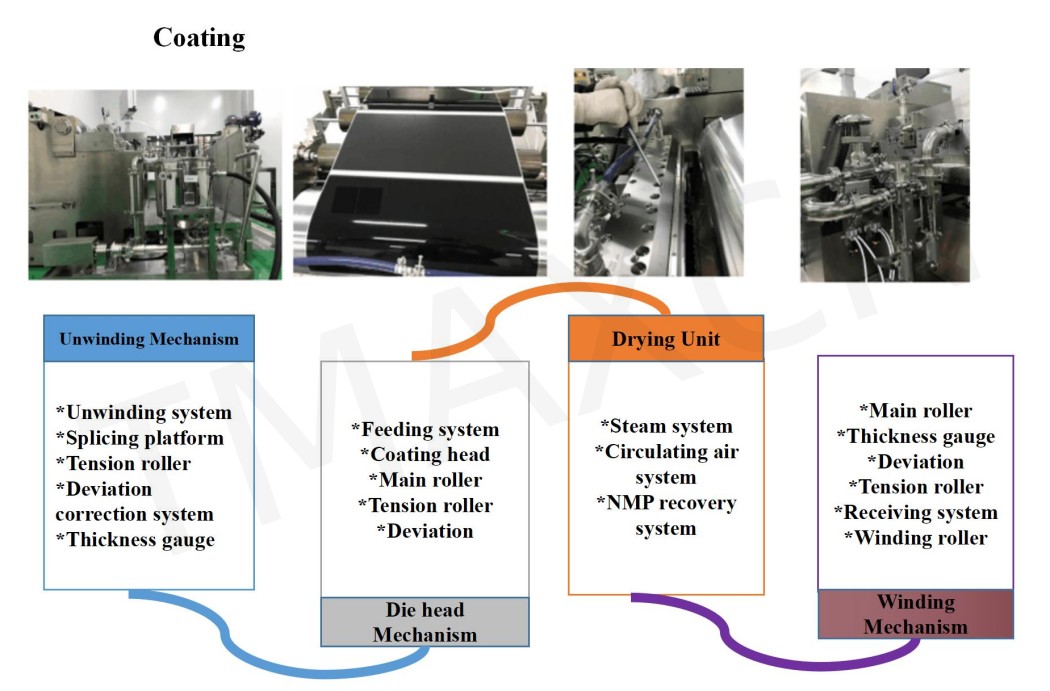

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915