- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- 2024-02-01

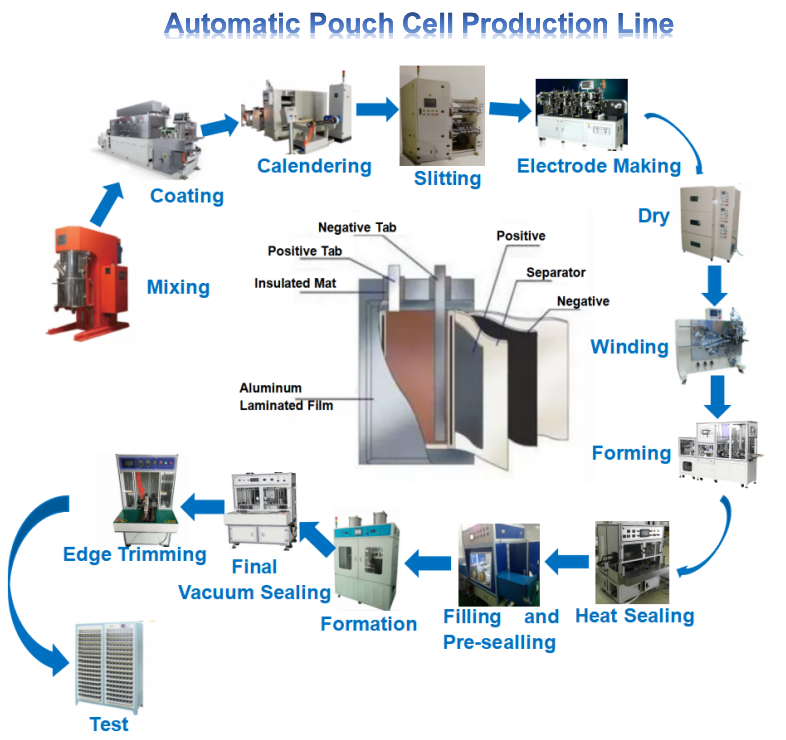

A Pouch Cell-Making Machine is a specialized piece of equipment designed for the automated production of pouch cells, a type of lithium-ion battery. Pouch cells are characterized by their flexible and flat structure, making them suitable for a wide range of applications, including portable electronics, electric vehicles, and energy storage systems. The Pouch Cell manufacturing Machine plays a crucial role in the efficient and precise fabrication of these batteries. Here's an in-depth look at its key functions:

Electrode Coating:

The machine begins the process by coating thin layers of electrode materials, typically composed of anode and cathode materials, onto current collectors. This step is critical for ensuring uniform and precise application of the active materials.

Calendering:

After coating, the electrode materials undergo a calendering process. The machine compresses and smoothens the electrodes to achieve the desired thickness and density. Calendering enhances the structural integrity of the electrodes, optimizing their performance within the cell.

Slitting:

Once the electrodes are prepared, a slitting mechanism is employed to cut them into specific widths. This step is crucial for tailoring the electrodes to the required dimensions, facilitating the subsequent assembly process.

Electrode Stacking:

The machine stacks the prepared electrodes in an alternating configuration with separator layers. The separator prevents direct contact between the positive and negative electrodes, avoiding short circuits and enhancing the safety and performance of the pouch cell.

Pouch Forming:

In this stage, the electrode stack is placed into a flexible pouch material, often made of aluminum or other materials. The machine then forms and seals the pouch, creating the distinctive flat and flexible structure of the pouch cell.

Electrolyte Filling:

The machine facilitates the injection of electrolyte into the formed pouch. The electrolyte is a conductive solution that enables the flow of ions between the electrodes during the battery's charge and discharge cycles.

Sealing:

A sealing mechanism ensures the hermetic closure of the pouch. This step is crucial for maintaining the integrity of the pouch cell, preventing electrolyte leakage, and ensuring long-term reliability.

Formation:

The formed pouch cells undergo an initial charge and discharge cycle in a controlled environment. This formation process stabilizes the electrochemical reactions within the cell, optimizing its performance.

Testing and Quality Control:

Various testing stations within the machine assess the performance and quality of each pouch cell. This includes voltage tests, capacity tests, and impedance tests, ensuring that only cells meeting stringent standards proceed to the next stages.

Tab Welding:

Tabs or leads are welded to the electrodes to provide electrical connections for the pouch cell. This step is crucial for integrating the cells into battery packs or electronic devices.

Cutting and Trimming:

The finished pouch cells undergo cutting and trimming processes to achieve their final dimensions. This ensures uniformity and adherence to design specifications.

Automation and Control:

The entire process is managed and controlled by an automated system. Automation enhances efficiency, reduces errors, and ensures consistency in the production of pouch cells.

The Pouch Cell Assembly line multifaceted functions contribute to the mass production of pouch cells with precision, reliability, and efficiency, supporting advancements in lithium-ion battery technology.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915