- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- 2024-02-19

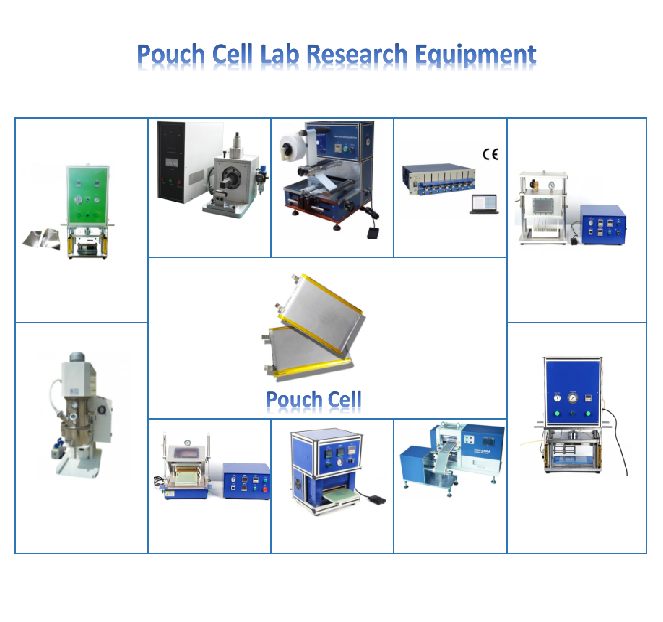

Pouch Cell Lab Equipment refers to the specialized equipment used in laboratory settings for the research, development, and testing of pouch cells, a type of lithium-ion battery. These lab-scale facilities are crucial for understanding the fundamental aspects of battery technology, optimizing designs, and conducting experiments before scaling up to industrial production. The production conditions in a pouch cell laboratory typically include the following aspects:

Cleanroom Environment:

Pouch cell labs often operate in cleanroom environments to minimize contamination. Cleanrooms are designed to control airborne particles, temperature, humidity, and other environmental factors that could affect the precision and reliability of battery testing.

Gloveboxes:

Gloveboxes with controlled atmospheres are commonly used in pouch cell labs. These sealed containers allow researchers to handle and manipulate sensitive materials, such as electrode materials and electrolytes, in an inert environment, usually filled with argon or nitrogen.

Safety Measures:

Safety is a top priority in battery labs. Researchers adhere to strict safety protocols when handling chemicals, conducting experiments, and operating equipment. Safety features may include emergency shut-off systems, ventilation systems, and personal protective equipment (PPE).

Temperature and Humidity Control:

Pouch cells are sensitive to temperature and humidity variations. Lab equipment includes environmental control systems to maintain stable conditions, ensuring consistent and reproducible experimental results.

Lab-scale electrode coating machines are used to apply thin layers of electrode materials onto current collectors. This equipment is crucial for developing and testing different coating formulations on a small scale.

Calendering machines in the lab help researchers optimize the thickness and density of coated electrodes. This step is essential for understanding the impact of calendering on electrode performance.

Pouch Forming Setup:

Lab-scale equipment for pouch forming allows researchers to experiment with different pouch materials and sealing techniques. This setup helps us understand the pouch formation process and its impact on cell performance.

Testing Stations:

Pouch cell labs are equipped with various testing stations to evaluate cell performance. This includes testing for voltage, capacity, cycle life, and other critical parameters. Advanced diagnostic tools may be used for in-depth analysis.

Electrolyte Filling Systems:

Lab-scale electrolyte filling systems enable researchers to inject electrolytes into pouch cells precisely. This step is crucial for studying the impact of electrolyte formulations on cell behavior.

Formation Chambers:

Formation chambers provide a controlled environment for pouch cells' initial charge and discharge cycles. This step is essential for stabilizing the cell's electrochemical processes.

Data Acquisition Systems:

Sophisticated data acquisition systems are employed to collect and analyze data from experiments. These systems help researchers monitor and understand the performance of pouch cells under different conditions.

Scale-Up Considerations:

Pouch cell labs may also incorporate equipment and setups that allow researchers to explore scale-up possibilities. Understanding how processes developed in the lab can be transitioned to larger production scales is crucial for industrial applications.

The production conditions in a Pouch Cell Lab are designed to create a controlled and precise environment, enabling researchers to investigate and optimize various aspects of pouch cell technology before moving to larger-scale production. Safety, precision, and reproducibility are paramount in these settings.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915