- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

Automatic Layer By Layer Battery Electrode Stacking Machine For Pouch Cell

Model Number:

MSK-111A-EType:

Electrode Stacker MachineDimension(L*W*H):

200x150mmNet Weight:

260 kgCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

Automatic Layer By Layer Battery Electrode Stacking Machine For Pouch Cell

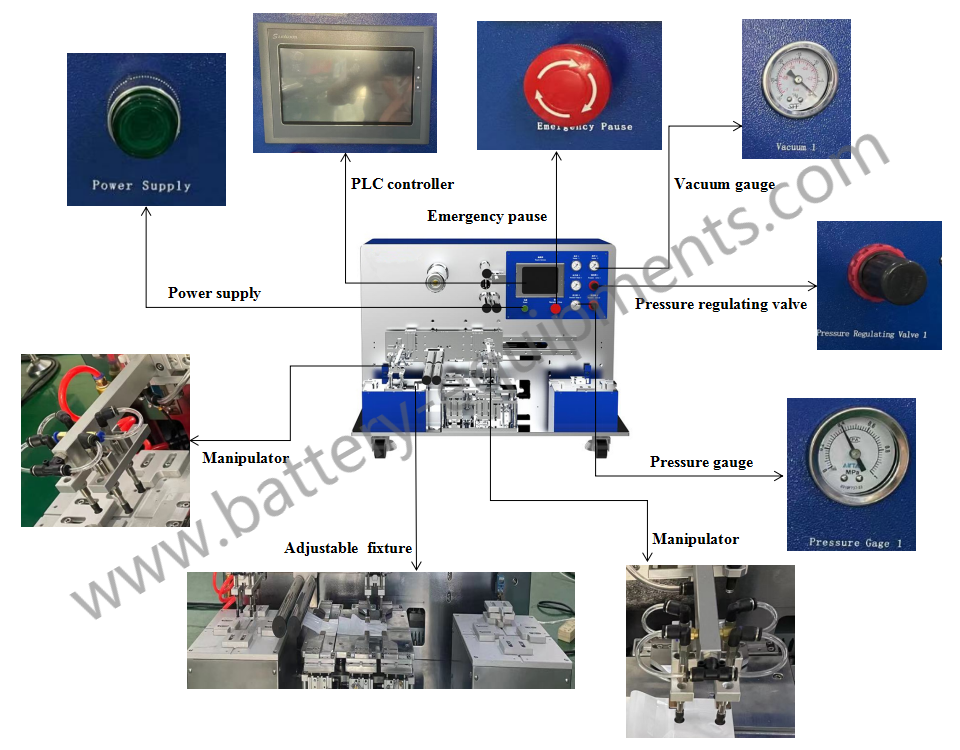

MSK-111A-E is a high-accuracy automatic stacking machine with many advanced features to ensure a stable, repeatable and precise electrode stacking. In its "Z" fashion stacking method, Anode and Cathode electrodes are alternatively stacked with the seperator film in between.

Advanced Features:

PLC Touch Screen Control allows easy condition settingContinuous "Z" fashion stacking with a separator

Auto electrode pick-up & stacking via vacuum suction manipulator

Adjustable mechanical fixture for accurate electrodes positioning

Unreeling rotors for separator film feeding

Auto-tension control for separator film delivery

One set of 80x50mm stocking die fixture is included for immediate use.

SPECIFICATIONS:

|

Working Voltage |

AC220V 50/60Hz |

|

Power |

1KW |

|

Stackable Size |

200x150mm |

|

Stackable Layers |

Upto 500 layers |

|

Max. Electrode Thickness |

Piled up thickness < 30 mm |

|

Aligning Accuracy |

±0.5 mm for stacked electrodes |

|

Acceptable Separator Roll Size |

I.D>3'' (76mm) O.D<9.8'' (250mm) |

|

Stacking Fixture |

One set of 200 x 150mm stacking die fixture is included for immediate use. If you need different size electrode stacking, please inform us before order. We will make for your at extra cost. Allowable customization size: Max. 200mm x 200mm; Min. 80 mm x 50 mm |

|

Vacuum Pump |

An Oilless Vacuum pump (28L/min, 140W) is built-in to enable the vacuum suction function of the electrode pick-up/stacking manipulator. |

|

Suggested Air Pressure |

0.5 - 0.8 MPa (Air compressor is not included in the standard package. |

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915