- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

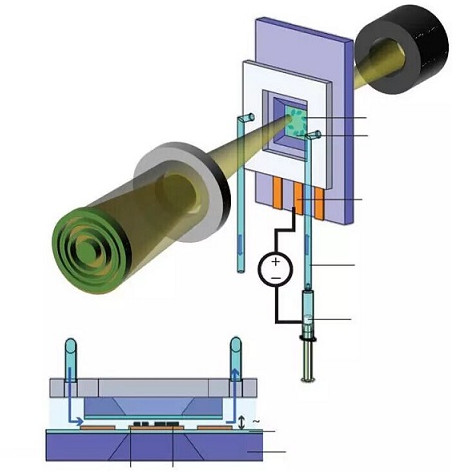

Split-able Pouch Cell Tester with Quartz Window for In-situ Analysis of Battery Electrode

Model Number:

TMAX-EQ-SPCWDimension(L*W*H):

Cathode Die: 57mm (L) x 44mm (W), Anode Die: 58mmNet Weight:

3 kgCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

Split-able Pouch Cell Tester with Quartz Window for In-situ Analysis of Battery Electrode

SPECIFICATIONS:

|

Design Features

|

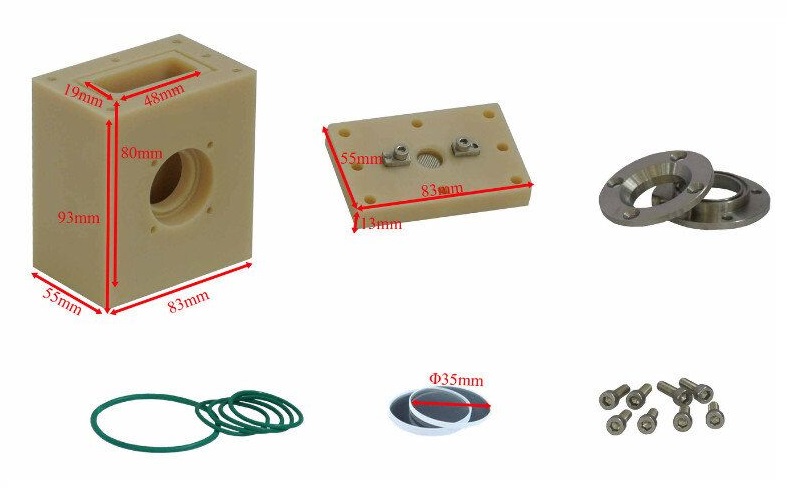

1. 30 mm diameter quartz window installed on two sides of pouch cell for transparency measurement.

2. Pouch cell is sealed by PTFE O-ring without liquid and gas leaking.

3. One pressure gauge installed on top to monitor pressure. You may remove the gauge and use 1/4 female port to inject electrolyte into the pouch cell.

4. Pouch cell is easy assembling by only four cap mounting screws.

5. It is easy to separate after test for microstructure analysis.

6. Space saving, compact design allows you put it into the glove box. |

|

Material

|

1. Nylon or PEEK (Poly Ether Ether Ketone) selectable from the product options bar.

2. Body:Electrolyte corrosive-proof Nylon which can sustain with temperature up to 80ยบC and O-ring: Sealed by electrolyte corrosive-proof PTFE O-rings.

3. Body:PEEK (Poly Ether Ether Ketone), which is a semicrystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures and O-ring: Sealed by electrolyte corrosive-proof FKM O-rings. |

|

Electrode Sheet dimension

|

1. Standard size: Cathode Die: 57mm (L) x 44mm (W). with 10mm (L) x 10mm (W) protrude current collector

2. Anode Die: 58mm (L) x 45mm (W). with 10mm (L) protrude current collector

3. Customized size pouch cell is available upon request. |

|

Application Note

|

1. In order to make metal air pouch cell, you can drill holes in the case. We can help you do that at an extra cost.

2. You may use die cutter to prepare electrode via layer by layer or make winding type pouch cell electrode (click picture below to see the machine).

3. You may need an ultrasonic welder to welding electrode tape to connect to the split cell. |

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915