- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

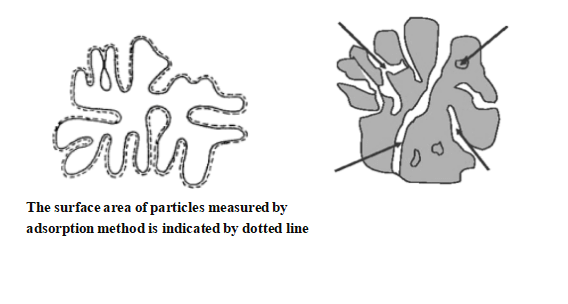

One Analysis Stations Automatic BET Surface Area and Porosimetry System

Model Number:

TMAX-3H-2000PS1Compliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

One Analysis Stations Automatic BET Surface Area and Porosimetry System

Test Reports:

Adsorption and desorption isotherm;

BET specific surface measurement (single point/multi-point method)

Langmuir Specific surface;

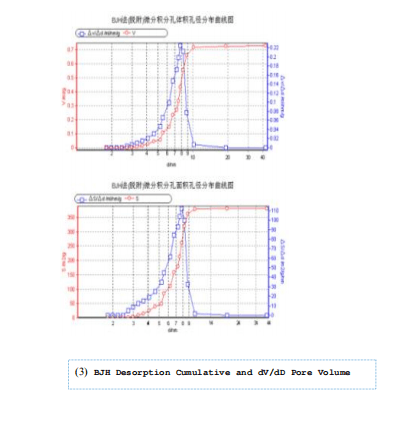

BJH method pore volume and pore size distribution;

MK-plate method (parallel-plate model) pore volume and pore size distribution;

D-R method micro-hole analysis;

t-plot method (boder) micro-pore analysis;

H-K method (Original) micro pore analysis;

Specifications

|

|

3H-2000PS1 |

3H-2000PS2 |

3H-2000PS4 |

|

|

Analysis Stations |

1 |

2 |

4 |

|

|

Measurement types: |

B.E.T., STSA, adsorption isotherm, desorption isotherm |

|||

|

Surface area range: |

0.01m2/g to no known upper limit |

|||

|

Pore size range: |

0.35 to >400nm (3.5 to >4000 Å) |

|||

|

Minimum pore volume: |

(STP) 0.0001 cc/g |

|||

|

|

|

|

|

|

|

Nitrogen |

√ |

√ |

√ |

|

|

Other non-corrosive gases (Ar, CO2, H2, C4H10, etc.) |

√ |

√ |

√ |

|

|

Preparation Ports |

2 |

2 |

4 |

|

|

Methods |

Vacuum |

Vacuum |

Vacuum |

|

|

Temperature range: |

ambient - 450ºC*, 1ºC intervals |

|||

|

|

|

|||

|

Accuracy |

±5ºC |

|||

|

Accuracy (% of span) |

±0.1 |

±0.1 |

±0.1 |

|

|

Minimum pressure (mm Hg) resolution |

0.016 |

0.016 |

0.016 |

|

|

Minimum relative pressure P/Po (N2) resolution |

2 x 10-5 |

2 x 10-5 |

2 x 10-5 |

|

|

|

|

|

|

|

|

Dimensions (WxDxH) |

L51cm x W58 cm xH 83cm |

|||

|

Weight |

32 kg (80 lbs.) |

|||

|

Electrical |

110-240 V, 50/60 Hz |

|||

The 3H-2000PS Series—designed for today’s laboratory

• Affordably-priced—perfect for any laboratory.

• Space saving—each unit takes up less bench space than an open 3-ring binder.

• Versatile—a wide range of characterization techniques for powdered and porous materials.

• Flexible operation—analysis type independent for each station (BET and/or pore size measurement).

•Prepare two samples by vacuum or flow methods simultaneously with sample analysis—at different temperatures if required.

• Access degasser during analysis to start/stop flow or vacuum degassingwith Analysis Interrupt.

•Eliminate cell calibration with classical helium-void-volume mode.

• Upgradeable—can adapt to meet your expanding or changing laboratory needs.

Unique Features

1. Unique and Innovative mainifold gas control system

2. Use of air control valve to avoid the heat effect of electromagnetic valve

3. Two independent vacuum systems permit simultaneous preparation of two samples while analyzing another.

4. Unique sample pretreatment anti pollution device, effectively prevent powder into the degas and analysis system

5. Long duration dewar provides virtually 70 hours analysis capability

Selection Guide

|

|

3H-2000PS1 |

3H-2000PS2 |

3H-2000PS4 |

3H-2000PM1 |

3H-2000PM2 |

|

Degas Stations |

2 |

2 |

4 |

2 |

2 |

|

Analysis Stations |

1 |

2 |

4 |

1 |

2 |

|

P0 Test |

√ |

√ |

√ |

√ |

√ |

|

BET |

√ |

√ |

√ |

√ |

√ |

|

Total volume |

√ |

√ |

√ |

√ |

√ |

|

Mesopore(p/p0>10-4) |

√ |

√ |

√ |

√ |

√ |

|

Micropore(p/p0<10-4) |

--- |

--- |

--- |

√ |

√ |

|

Isothe |

√ |

√ |

√ |

√ |

√ |

|

Vacuum Pump |

√ |

√ |

√ |

√ |

√ |

|

Turbo Vacuum Pump |

--- |

--- |

--- |

√ |

√ |

|

1000 torr Transducers |

√ |

√ |

√ |

√ |

√ |

|

10 torr Transducers |

--- |

--- |

--- |

Optional |

Optional |

|

1 torr Transducers |

Optional |

|

Optional |

√ |

√ |

|

0.1 torr Transducers |

--- |

--- |

--- |

Optional |

Optional |

|

Degas Cold Trap |

--- |

--- |

--- |

√ |

√ |

|

Analysis Cold Trap |

--- |

--- |

--- |

√ |

√ |

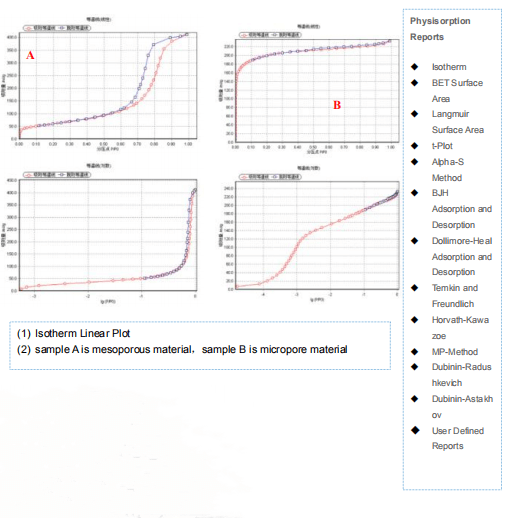

3H-2000PS Series Analyzer Test Reports

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915