- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

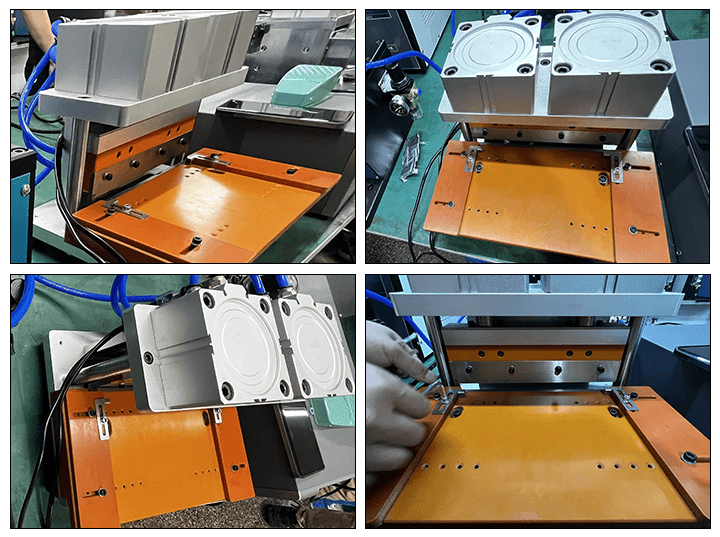

Lithuim Battery Double Tabs Cutting Machine for Pouch Cell Making

Model Number:

TMAX-QJH300Compliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportDelivery Time:

3 Days

Wechat:13506084915

Lithuim Battery Double Tabs Cutting Machine for Pouch Cell Making

Introduction

It is mainly suitable for the fixed-length cutting and trimming of the electrode tabs of the batteries, and the double cutters are mutually insulated.

Main features

*Shangyin linear slide rail group is used for guiding, and the guiding accuracy is extremely high to ensure zero clearance between the upper and lower cutters and long service life;

*The upper and lower cutters are made of high-speed steel, with sharp blades;

*Double cutters are insulated from each other;

*The cylinder controls the cutter to trim the battery pole piece and tab, which is easy to be automated;

*Set the product positioning tray to facilitate the positioning and placement of the batteries.

*Beautiful, reliable, convenient and fast;

Instruction

Put the product into the edge position to be trimmed and hold the position, press the touch switch, the double cutter is driven up and down by the large cylinder, the double cutter is insulated from each other, and the tabs are cut to complete the trimming of the product.

Technical parameter

|

Specification |

Within 250mm of the center distance of the tabs |

|

Single cutter |

80mm long |

|

Insulation |

The left and right cutters are insulated from each other |

|

Position |

The blade positioning block of the tab cutting machine and the battery side positioning block are adjustable |

|

Cutter life |

1 million times/grinding |

|

Speed |

Air pressure 600 times/hour |

|

Air compressed air source |

0.5Mpa~0.7Mpa |

|

Dimensions |

L230*W200*H250mm |

|

Weight |

50Kg |

![]()

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915