- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

Laboratory Powder Ball Grinding Grinder Mill Machine With Ball Mill Tank

Model Number:

TMAX-Mill01Type:

Planetary Ball Mill MachineDimension(L*W*H):

0.1L*4Net Weight:

70KGCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

Laboratory Powder Ball Grinding Grinder Mill Machine With Ball Mill Tank

SPECIFICATION

1 The laboratory planetary ball milling machine is Used in college, university, scientific research units and enterprises laboratory for rapid batch study sample grinding to the colloidal fineness (sample diameter usually is less than 1 mm , solid particles is generally not more than 3 mm, soil allows 10 mm, Grinding min size up to 0.1um), it is can also be used in the mechanical alloying, and blending, homogenization and scattered.

2 Adopt gear oil seal, Increase service life and reduce noise.

3 Suitable for dry, wet and vacuum grinding mill.

|

Model |

(Oil Seal Mute) Planetary Ball Mill TMAX-Mill01 |

|

Source voltage |

AC110V/220V 50/60HZ |

|

Total power |

0.55KW |

|

Warranty |

Two year limited with lifetime support |

|

Voice processing |

Oil seal mute processing technology |

|

Ball milling tank volume |

100ml*4 |

|

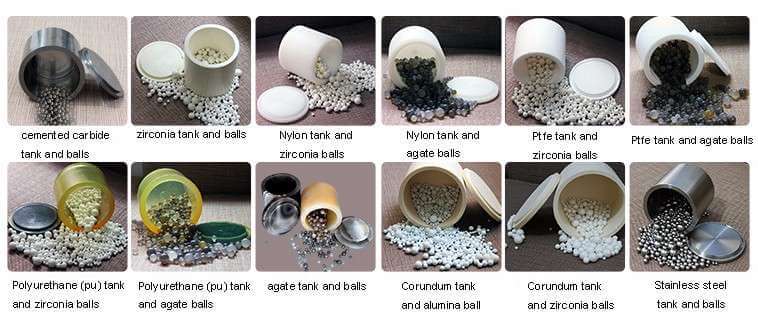

Milling tank materials |

Metal material: 304 stainless steel, cemented carbide (YG8) |

|

Nonmetallic material : ceramic/corundum/alumina, zirconia, agate |

|

|

High polymer material : nylon, polyurethane, ptfe |

|

|

Ball mill medium |

Stainless steel, ceramic/corundum/alumina, zirconia, agate, cemented carbide |

|

Max charge of tank |

No more 1/3 of the volume |

|

Filling materials size |

Crispy material is less than 10 mm, other less than 3 mm |

|

Single tank fill quantity |

100ml tank with 33ml material |

|

Output material size |

Min 0.1um |

|

Grinding mode |

Dry/wet/high-energy alloying grinding/vacuum/cryogenic grinding, last two model need customized |

|

Max continuous working time |

72 hours |

|

Revolution speed |

Revolution : 0-450r/min Rotation : 0-900r/min Speed ratio : 1:2 |

|

Dimension |

600*400*500mm |

|

Weight |

60kg |

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915