- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

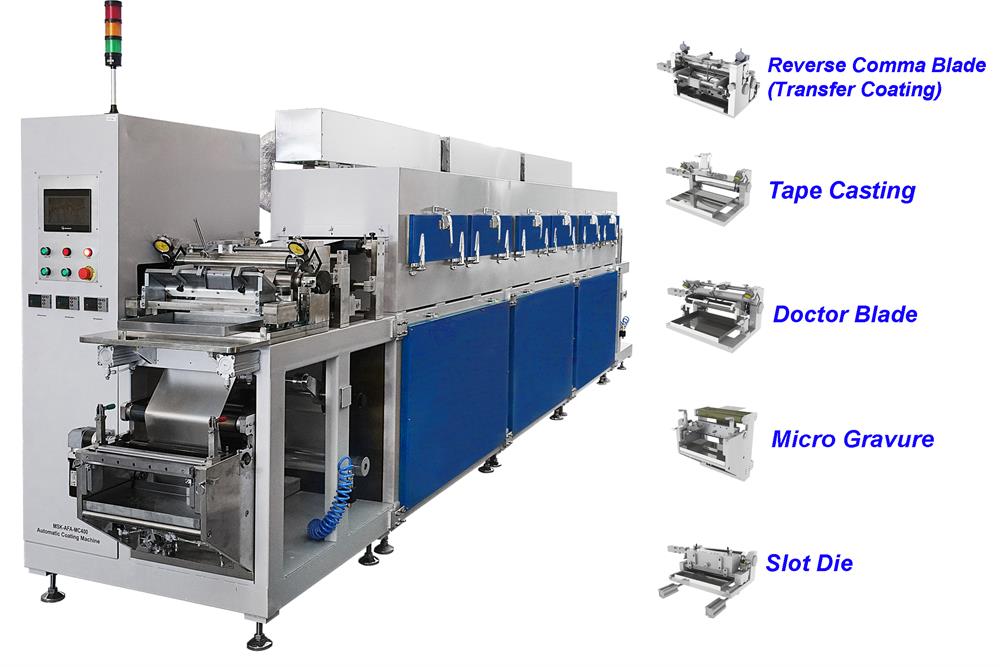

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- 2024-03-15

Roll-to-Roll (R2R) calender machines are essential components in the battery manufacturing process, particularly in the production of electrode materials. Here's an explanation of the importance of R2R calender machines in the battery manufacturing process:

Continuous Production:

R2R calender machines enable continuous and high-throughput production of electrode materials. In contrast to batch processing, the roll-to-roll approach allows for a continuous and seamless operation, increasing efficiency and reducing production time.

Precision in Thickness Control:

These machines provide precise control over the thickness of electrode materials. The calendering process, which involves passing the electrode material through rollers under pressure, ensures uniform thickness across the entire length of the roll. This precision is crucial for maintaining consistency in battery performance.

Uniformity in Coating:

R2R calender machines play a role after the electrode coating process. They contribute to the uniformity of the coated electrode materials, ensuring a consistent distribution of active materials. This uniformity is vital for the electrochemical performance and overall efficiency of the battery.

Enhanced Electrode Density:

The calendering process applied by R2R machines enhances the density of the electrode materials. This is important for optimizing the electrochemical reactions within the battery and improving its energy storage capacity.

Porosity Control:

The calendering process helps control the porosity of the electrodes. By adjusting the pressure during calendering, manufacturers can tailor the porosity to meet specific design requirements, impacting the battery's rate capability and overall performance.

Improved Structural Integrity:

Roll to roll calender contributes to the improved structural integrity of the electrodes. This is particularly crucial for flexible and thin-film batteries, where maintaining mechanical stability is essential to prevent damage during handling and use.

Scalability and Cost Efficiency:

R2R processing is scalable, making it suitable for large-scale production. The continuous nature of roll-to-roll manufacturing allows for increased production volumes, contributing to cost efficiency in the manufacturing process.

Integration into Battery Manufacturing Lines:

R2R calender machines are integrated into battery manufacturing lines as a key step in the overall production process. They are strategically positioned after the coating and drying stages, preparing the electrode materials for the subsequent assembly of battery cells.

Consistency Across Production Batches:

The use of R2R calender machines ensures consistency not only within a single production batch but also across multiple batches. This is crucial for meeting quality standards and delivering batteries with reliable and predictable performance.

Quality Assurance and Performance Optimization:

R2R calender machines contribute to quality assurance by enabling manufacturers to fine-tune the properties of electrode materials. This optimization is essential for meeting specific performance criteria and producing batteries that meet the demands of various applications.

In summary, R2R calender machines are vital in the battery manufacturing process, offering continuous production, precise control over thickness, uniform coating, enhanced electrode properties, and scalability. These machines contribute significantly to the efficiency, consistency, and quality of battery production for various applications, including energy storage and electric vehicles.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915