- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- 2023-06-15

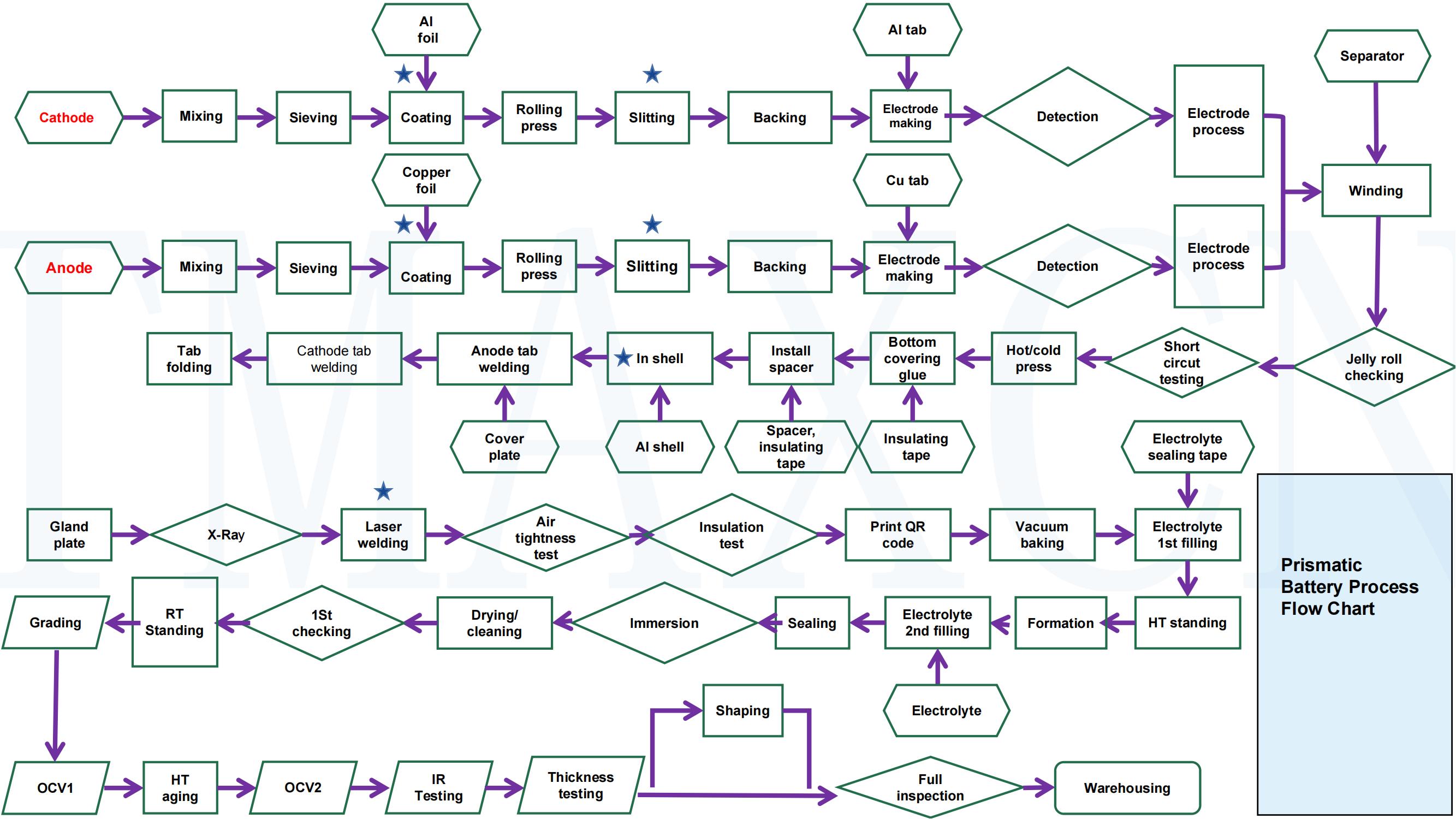

Introduction:

Are you looking to explore the cutting-edge world of advanced lithium-ion battery production? Look no further than the Prismatic Cell Fabrication Plant. This state-of-the-art facility is revolutionizing the manufacturing process for prismatic cells, offering unrivaled efficiency, quality, and reliability. Let's dive into the features and advantages that make the Prismatic Cell Fabrication Plant the go-to choice for battery manufacturers worldwide.

Advanced Automation and Precision:

At the heart of the Prismatic Cell Fabrication Plant is its advanced automation capabilities. With precision-driven machinery and intelligent control systems, the plant ensures consistent and precise electrode preparation, assembly, and sealing processes. This translates to increased production efficiency, reduced human error, and enhanced product uniformity.

Versatility and Customization:

The Prismatic Cell Fabrication Plant boasts the ability to accommodate various cell sizes, configurations, and chemistries, providing manufacturers with unparalleled flexibility. Whether you're producing batteries for electric vehicles, consumer electronics, or energy storage systems, the plant can be tailored to meet your specific requirements and deliver optimal results.

Enhanced Quality and Reliability:

By harnessing the latest technological advancements, the Prismatic Cell Fabrication Plant guarantees superior battery quality and reliability. From electrode coating and stacking to precise winding and encapsulation, every step of the manufacturing process is optimized to produce cells with exceptional performance, longer cycle life, and enhanced safety features.

Cost Efficiency and Scalability:

The Prismatic Cell Fabrication Plant offers a cost-efficient solution for battery manufacturers. Its automated processes minimize labor costs, reduce waste, and optimize resource utilization, resulting in improved productivity and a higher return on investment. Furthermore, the plant's scalable design allows for seamless expansion to meet growing production demands.

Research and Development Support:

With a dedicated focus on innovation, the Prismatic Cell Fabrication Plant provides a platform for research and development activities. Manufacturers can explore new materials, electrode designs, and manufacturing techniques to stay ahead of the curve and drive advancements in battery technology. The plant's flexibility and adaptability enable quick iterations and prototyping, facilitating faster time-to-market for new battery solutions.

Conclusion:

The Prismatic Cell Fabrication Plant represents the pinnacle of excellence in battery manufacturing. Its advanced automation, versatility, and commitment to quality make it the ideal choice for businesses seeking to stay competitive in the ever-evolving energy storage industry. By leveraging the plant's capabilities, manufacturers can achieve higher productivity, superior product performance, and a sustainable edge in the market. Contact us today to embark on a transformative journey in prismatic cell production and revolutionize your battery manufacturing process.

Recommend two production lines:

100MWH EV Car Power Battery LFP NCM Prismatic Cell Production Line Pilot Line

Automatic Lithium-ion Prismatic Battery Production Plant

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915