- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

blog

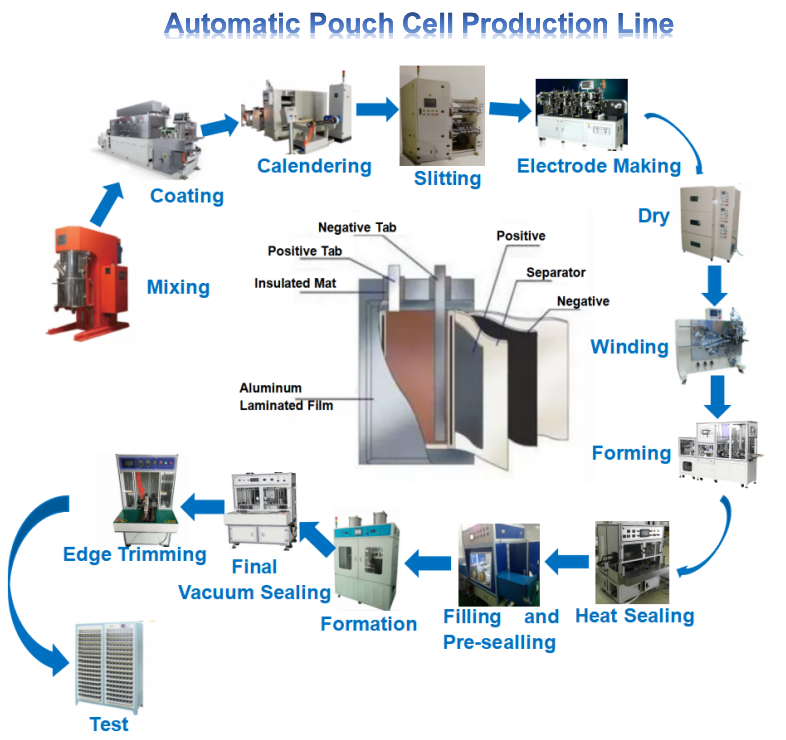

Pouch Cell Research Plant

- 2023-06-14

Pouch Cell Research Plant requires various equipment and considerations during its establishment. Here are some essential equipment and key considerations:

Glove Box: A glove box with a controlled atmosphere is necessary for handling and assembling pouch cell components in an inert environment, typically filled with argon or nitrogen gas. It provides an oxygen- and moisture-free environment to ensure the integrity of the pouch cell.

Electrode Coating Machine: An electrode coating machine is used to apply the active materials, such as lithium-based compounds, onto the current collector foils. This machine allows for precise and uniform coating thickness, ensuring consistent electrode performance.

Electrode Slitting Machine: An electrode slitting machine is employed to cut the coated electrode into desired widths. It helps achieve the required dimensions for pouch cell assembly.

Pouch Cell Assembly Machine: This machine automates the process of assembling the pouch cell. It typically includes functions such as stacking the electrodes, adding separator layers, inserting tabs, and sealing the pouch.

Electrolyte Filling System: An electrolyte filling system is used to inject the electrolyte into the assembled pouch cell. It ensures the correct electrolyte volume and proper sealing of the pouch.

Pouch Sealing Machine: This machine seals the pouch cell to prevent electrolyte leakage and maintain the integrity of the cell. It applies heat or pressure to seal the edges of the pouch.

Battery Testing and Characterization Equipment: Various testing and characterization equipment are essential for assessing the performance of pouch cells. This includes equipment for measuring voltage, current, capacity, internal resistance, and other electrochemical properties.

Considerations during establishment:

Safety Measures: Ensure proper safety measures are in place, including fume hoods, fire suppression systems, and personal protective equipment (PPE) for handling chemicals and working with electrical equipment.

Environmental Control: Maintain a controlled environment with temperature and humidity control to ensure accurate and consistent testing conditions.

Quality Control: Implement rigorous quality control processes to monitor the performance and consistency of the manufactured pouch cells. This includes regular testing, data analysis, and process optimization.

Compliance with Regulations: Adhere to relevant regulations and safety standards for battery manufacturing and handling hazardous materials. Stay updated with industry guidelines and ensure compliance with environmental regulations.

Continuous Research and Development: Pouch cell research plants should have provisions for ongoing research and development activities. This includes a dedicated team for exploring new materials, optimizing manufacturing processes, and improving cell performance.

Collaboration and Knowledge Sharing: Foster collaboration with research institutions, industry partners, and academic experts to stay informed about the latest advancements and exchange knowledge in pouch cell research.

Glove Box: A glove box with a controlled atmosphere is necessary for handling and assembling pouch cell components in an inert environment, typically filled with argon or nitrogen gas. It provides an oxygen- and moisture-free environment to ensure the integrity of the pouch cell.

Electrode Coating Machine: An electrode coating machine is used to apply the active materials, such as lithium-based compounds, onto the current collector foils. This machine allows for precise and uniform coating thickness, ensuring consistent electrode performance.

Electrode Slitting Machine: An electrode slitting machine is employed to cut the coated electrode into desired widths. It helps achieve the required dimensions for pouch cell assembly.

Pouch Cell Assembly Machine: This machine automates the process of assembling the pouch cell. It typically includes functions such as stacking the electrodes, adding separator layers, inserting tabs, and sealing the pouch.

Electrolyte Filling System: An electrolyte filling system is used to inject the electrolyte into the assembled pouch cell. It ensures the correct electrolyte volume and proper sealing of the pouch.

Pouch Sealing Machine: This machine seals the pouch cell to prevent electrolyte leakage and maintain the integrity of the cell. It applies heat or pressure to seal the edges of the pouch.

Battery Testing and Characterization Equipment: Various testing and characterization equipment are essential for assessing the performance of pouch cells. This includes equipment for measuring voltage, current, capacity, internal resistance, and other electrochemical properties.

Considerations during establishment:

Safety Measures: Ensure proper safety measures are in place, including fume hoods, fire suppression systems, and personal protective equipment (PPE) for handling chemicals and working with electrical equipment.

Environmental Control: Maintain a controlled environment with temperature and humidity control to ensure accurate and consistent testing conditions.

Quality Control: Implement rigorous quality control processes to monitor the performance and consistency of the manufactured pouch cells. This includes regular testing, data analysis, and process optimization.

Compliance with Regulations: Adhere to relevant regulations and safety standards for battery manufacturing and handling hazardous materials. Stay updated with industry guidelines and ensure compliance with environmental regulations.

Continuous Research and Development: Pouch cell research plants should have provisions for ongoing research and development activities. This includes a dedicated team for exploring new materials, optimizing manufacturing processes, and improving cell performance.

Collaboration and Knowledge Sharing: Foster collaboration with research institutions, industry partners, and academic experts to stay informed about the latest advancements and exchange knowledge in pouch cell research.

Remember that the specific equipment and considerations may vary depending on the scale and focus of the research plant. It is advisable to consult battery experts, equipment manufacturers, and industry guidelines to tailor the setup and operations to your specific research goals and requirements.

HOT PRODUCTS

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915