- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

blog

Pouch Cell Production Machine

- 2023-08-18

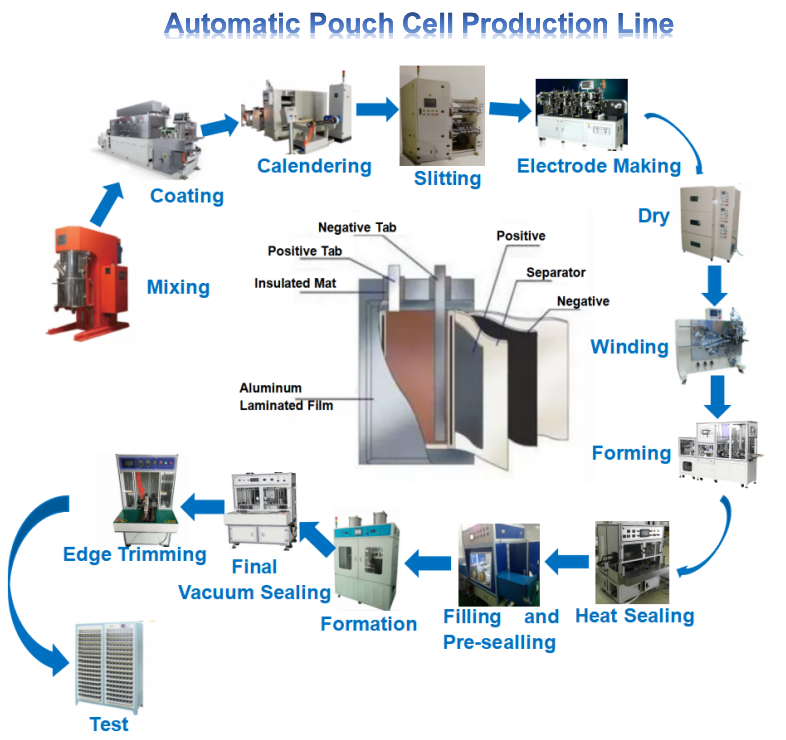

Pouch Cell Production Machine: Transforming Battery Manufacturing

The evolution of battery technology has revolutionized industries ranging from electric vehicles to portable electronics. Pouch cells, a type of lithium-ion battery, have gained prominence due to their lightweight and flexible design. Behind the scenes, advanced Pouch cell making Machine play a pivotal role in shaping the future of battery manufacturing. In this article, we will explore the key aspects of pouch cell production machines, their functions, and their impact on the battery industry.

Introduction to Pouch Cell Batteries:

Pouch cells are characterized by their flat, rectangular shape, which is achieved by encasing the electrode materials and electrolyte in flexible packaging. This design offers higher energy density and versatility, making pouch cells ideal for various applications.

Pouch Cell Production Machines: Essential Components of Battery Manufacturing:

Electrode Coating Machines: These machines are responsible for applying electrode materials onto current collectors with precision. The even distribution of cathode and anode materials ensures optimal battery performance.

Electrode Slitting Machines: After coating, the electrodes are cut into specific sizes using slitting machines. These machines ensure uniformity and accuracy in electrode dimensions.

Stacking and Assembling Equipment:Pouch Cell Lab Machine employ automated robotic systems to stack electrode layers and separators. This process forms the heart of the battery cell, with precise alignment to enhance energy density and performance.

Sealing and Welding Machines: Pouch cells are sealed to prevent electrolyte leakage and external contamination. Tab welding machines attach terminals to the electrode tabs, establishing electrical connections.

Electrolyte Filling Stations: Pouch cells are filled with electrolyte solutions using automated filling stations. Precise control over electrolyte volume ensures consistent cell performance.

Formation Chambers: Cells undergo formation cycles to stabilize their performance and optimize capacity. Formation chambers expose the cells to controlled charging and discharging cycles.

Formation and Testing Equipment: Comprehensive testing stations assess cell performance, capacity, voltage, and cycle life. These tests ensure that each pouch cell meets quality standards before integration.

Battery Pack Integration Lines: Pouch cells are integrated into larger battery packs, used in applications like EVs or energy storage systems. Assembly lines manage thermal management, safety systems, and electrical connections.

Impact on the Battery Industry:

Pouch cell production machines are shaping the battery industry in several ways:

Increased Efficiency: Automation and precision engineering reduce human error, increase production speed, and enhance overall efficiency in battery manufacturing.

Innovation and Customization: The modular design of these machines allows for flexibility in producing various battery configurations, enabling innovation in battery design.

Quality Assurance: Robust testing and quality control processes ensure that each pouch cell meets stringent performance and safety criteria.

Economic Advantages: Mass production enabled by these machines drives down costs, making advanced battery technologies more accessible to a wider range of industries.

Conclusion: A Powerhouse of Battery Innovation

The evolution of battery technology has revolutionized industries ranging from electric vehicles to portable electronics. Pouch cells, a type of lithium-ion battery, have gained prominence due to their lightweight and flexible design. Behind the scenes, advanced Pouch cell making Machine play a pivotal role in shaping the future of battery manufacturing. In this article, we will explore the key aspects of pouch cell production machines, their functions, and their impact on the battery industry.

Introduction to Pouch Cell Batteries:

Pouch cells are characterized by their flat, rectangular shape, which is achieved by encasing the electrode materials and electrolyte in flexible packaging. This design offers higher energy density and versatility, making pouch cells ideal for various applications.

Pouch Cell Production Machines: Essential Components of Battery Manufacturing:

Electrode Coating Machines: These machines are responsible for applying electrode materials onto current collectors with precision. The even distribution of cathode and anode materials ensures optimal battery performance.

Electrode Slitting Machines: After coating, the electrodes are cut into specific sizes using slitting machines. These machines ensure uniformity and accuracy in electrode dimensions.

Stacking and Assembling Equipment:Pouch Cell Lab Machine employ automated robotic systems to stack electrode layers and separators. This process forms the heart of the battery cell, with precise alignment to enhance energy density and performance.

Sealing and Welding Machines: Pouch cells are sealed to prevent electrolyte leakage and external contamination. Tab welding machines attach terminals to the electrode tabs, establishing electrical connections.

Electrolyte Filling Stations: Pouch cells are filled with electrolyte solutions using automated filling stations. Precise control over electrolyte volume ensures consistent cell performance.

Formation Chambers: Cells undergo formation cycles to stabilize their performance and optimize capacity. Formation chambers expose the cells to controlled charging and discharging cycles.

Formation and Testing Equipment: Comprehensive testing stations assess cell performance, capacity, voltage, and cycle life. These tests ensure that each pouch cell meets quality standards before integration.

Battery Pack Integration Lines: Pouch cells are integrated into larger battery packs, used in applications like EVs or energy storage systems. Assembly lines manage thermal management, safety systems, and electrical connections.

Impact on the Battery Industry:

Pouch cell production machines are shaping the battery industry in several ways:

Increased Efficiency: Automation and precision engineering reduce human error, increase production speed, and enhance overall efficiency in battery manufacturing.

Innovation and Customization: The modular design of these machines allows for flexibility in producing various battery configurations, enabling innovation in battery design.

Quality Assurance: Robust testing and quality control processes ensure that each pouch cell meets stringent performance and safety criteria.

Economic Advantages: Mass production enabled by these machines drives down costs, making advanced battery technologies more accessible to a wider range of industries.

Conclusion: A Powerhouse of Battery Innovation

Pouch cell production machines stand as the backbone of the battery manufacturing revolution. By combining precision, automation, and versatility, these machines enable the efficient production of high-performance pouch cell batteries. As demand for electric vehicles, consumer electronics, and renewable energy solutions continues to grow, the impact of pouch cell production machines on the battery industry will only become more profound, accelerating the transition to a more sustainable and technologically advanced future.

HOT PRODUCTS

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915