- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- 2023-07-12

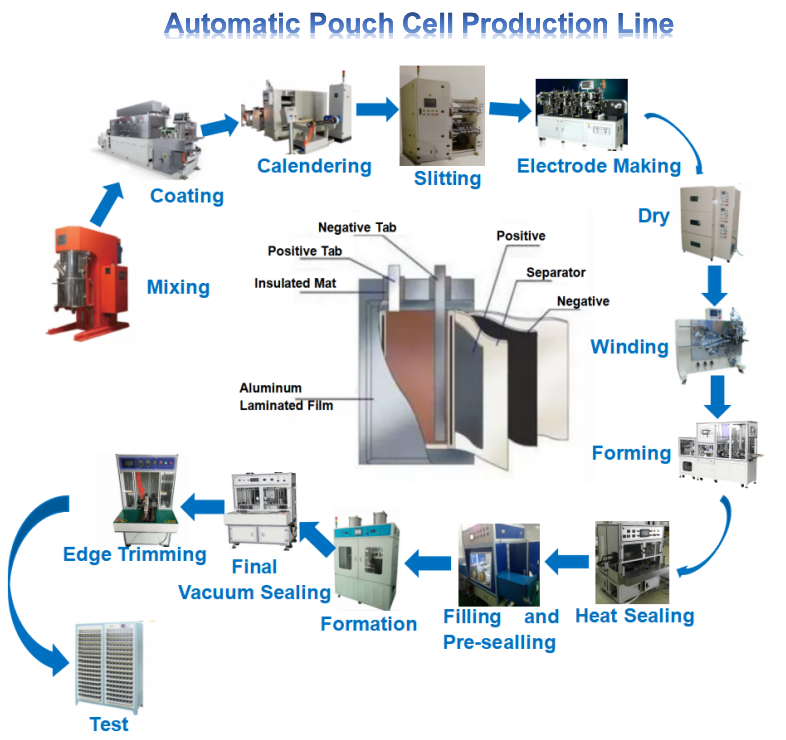

A pouch cell lab line refers to a pouch cell scale production line or equipment setup specifically designed for the manufacturing and testing of pouch cells, which are a type of lithium-ion battery. Pouch cells are widely used in portable electronics, electric vehicles, and energy storage systems. A pouch cell lab line typically consists of several key components and processes:

Electrode Preparation:

Coating: A coating machine is used to apply electrode slurry onto thin metal foils, such as aluminum or copper foils. The slurry contains active materials, binders, conductive additives, and solvents.

Drying: The coated electrodes are then dried in an oven to remove solvents and achieve proper adhesion of the active materials to the current collector foils.

Calendering: Calendering machines can be employed to compress and smoothen the dried electrodes, ensuring uniform thickness and density.

Electrode Stacking and Cell Assembly:

Stacking: The coated and dried electrode layers, along with separators, are accurately stacked in a precise order to form the cell's electrode stack. This process can be automated using stacking machines.

Tab Welding: Tabs, typically made of copper or aluminum, are attached to the electrode stack for electrical connections. Tab welding machines perform this welding process.

Encapsulation: The electrode stack is then encapsulated using a pouch film, typically made of a laminate material such as aluminum and plastic layers. Lamination machines can be used to seal and encapsulate the electrode stack within the pouch film.

Electrolyte Filling and Sealing:

Electrolyte Filling machine: The sealed pouch cells are filled with electrolyte, which is a conductive solution containing lithium salts. Electrolyte filling machines can be employed to ensure precise and controlled filling of the pouch cells.

Sealing: After electrolyte filling, the pouch cells are hermetically sealed to prevent leakage and ensure the integrity of the cell. Sealing methods such as heat sealing or ultrasonic welding are commonly used.

Formation and Testing:

Lithium battery Formation machine: The assembled pouch cells undergo a formation process to stabilize their electrochemical performance. This involves subjecting the cells to controlled charging and discharging cycles.

Testing: Pouch cells are subjected to various tests to evaluate their electrical performance, capacity, voltage, impedance, safety features, and overall quality. Testing equipment such as battery cyclers, impedance analyzers, and voltage meters are utilized for this purpose.

Safety and Quality Control:

Safety Measures: Pouch cell lab lines incorporate safety features and protocols to handle and store hazardous materials, ensure proper ventilation, and prevent accidents or thermal runaway events.

Quality Control: Rigorous quality control measures are implemented throughout the pouch cell lab line. This includes visual inspections, statistical process control, performance testing, and adherence to relevant industry standards.

A pouch cell lab line allows researchers, manufacturers, and battery developers to produce and test pouch cells on a smaller scale, enabling experimentation, optimization, and quality assurance before scaling up to larger production lines. It facilitates the development and improvement of pouch cell technology for various applications.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915