- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- 2023-04-25

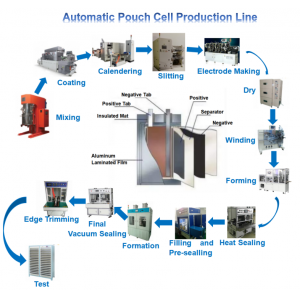

Pouch cell a type of rechargeable battery commonly used in various portable electronic devices such as smartphones, tablets, and laptops. The production process involves the assembly of a number of components into a compact and sealed pouch-shaped cell, which houses the battery's electrodes, electrolyte, and separator.

Pouch cell assembly plants related equipment

- Battery Electrode Cuter,

- battery stacking machine,

- pouch cell forming machine,

- pouch cell ultrasonic welder,

- pouch cell hot sealing machine ,

- pouch cell sealing machine and other equipment

The manufacturing process of a pouch cell typically involves several steps, including electrode coating, electrode stacking, cell winding, and pouch cell assembly. The electrode coating process involves applying a thin layer of active material to a metal substrate, which serves as the electrode's current collector. The coated electrodes are then stacked together with a separator material in between to form the cell's electrode assembly. The electrode assembly is then wound into a cylindrical shape and placed into a pouch-shaped casing made of a polymer material. The casing is then sealed and filled with an electrolyte solution.

To ensure the production of high-quality pouch cells, a number of sophisticated machines and equipment are required. These include electrode coating machines, electrode slitting machines, winding machines, sealing machines, and testing equipment. The production line is typically highly automated, with advanced control systems and quality control measures in place to ensure consistent product quality and safety.

The advantages of using a pouch cell include a high energy density, which allows for longer battery life in a smaller form factor. They are also known for their low internal resistance, which results in higher efficiency and less heat generation during use. In addition, pouch cells are highly customizable, with the ability to adjust the cell size, voltage, and capacity to suit specific device requirements.

In the production of pouch cells, attention must be paid to safety measures, as the use of lithium-ion batteries carries inherent risks. Careful handling of flammable materials, as well as proper training and equipment, are essential to ensure a safe and efficient production process.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915