- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- 2023-12-01

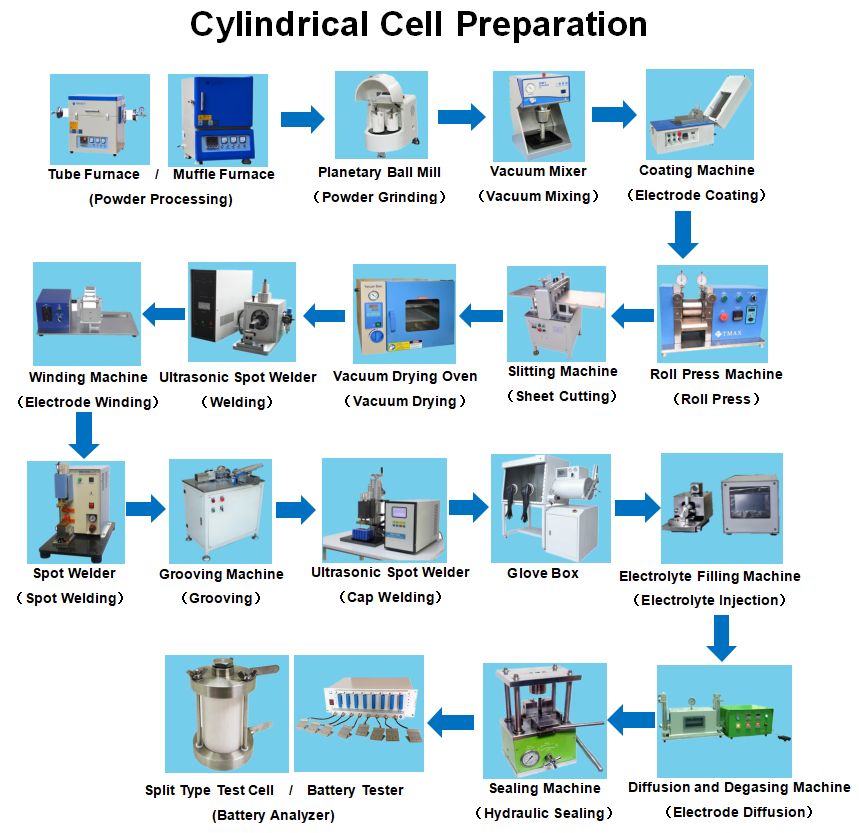

Technical Specifications:

Coating Material Compatibility:

Cylindrical Cell fabrication line should be designed to handle various coating materials used in battery manufacturing, such as electrode materials and electrolytes.

Substrate Compatibility:

Compatible with different types of battery substrates, including cathodes, anodes, and separators.

Coating Thickness Control:

Precise control over the coating thickness is crucial for ensuring the desired performance of the battery.

Drying System:

Efficient drying mechanisms to remove solvents from the coated electrodes or separators.

Uniformity:

Ensures uniform coating distribution on battery components for consistent performance.

Automation and Control System:

Advanced automation features and control systems for accurate monitoring and adjustment of critical parameters.

Primary Functions:

Electrode Coating:

The primary function is to apply a thin, uniform coating of electrode material onto the surface of battery components.

Electrolyte Coating:

In some cases, the Cylindrical Cell pilot line may be adapted to coat components with electrolyte materials, contributing to the overall performance of the battery.

Enhanced Performance:

Coating plays a critical role in enhancing the performance and efficiency of batteries by improving conductivity and stability.

Protection:

The coating acts as a protective layer, preventing issues like corrosion and degradation of battery components.

Efficiency and Throughput:

Automation ensures efficiency and high throughput, contributing to the overall productivity of battery manufacturing.

Quality Control:

Contributes to quality control by providing a consistent and controlled coating process.

Versatility:

Designed to handle various types and sizes of batteries used in different applications.

A Film Coating Machine in battery production is a specialized equipment ensuring the precision and reliability needed for the critical process of Cylindrical Cell Assembly Plant battery components.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915