- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- 2023-06-29

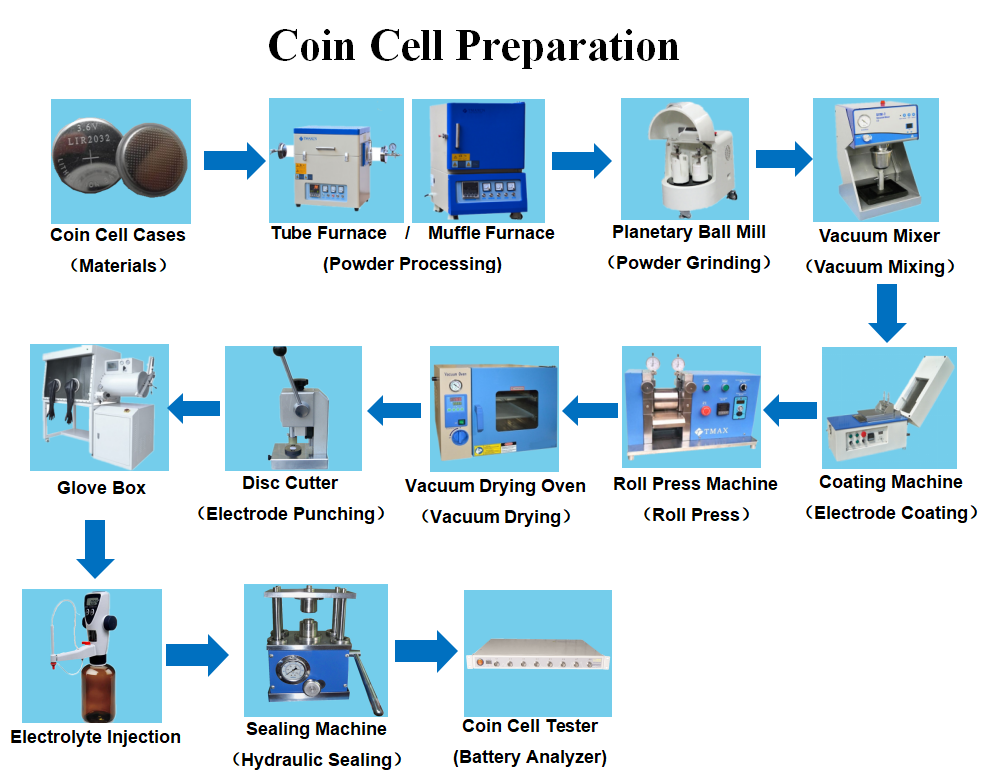

Unlocking the Future: The Significance of Coin Cell Assembly Line in Research and Development

Introduction:

Coin cells, also known as button cells, have long been an integral part of various electronic devices, powering everything from watches to medical devices. The development of advanced Coin Cell fabrication line has played a significant role in driving research and development in the field of energy storage. In this blog post, we will delve into the significance of Coin Cell fabrication lines in research and development, exploring how they enable innovation, accelerate progress, and pave the way for future advancements.

Accelerating Material and Electrode Research:

Coin Cell fabrication lines provide researchers with a crucial platform to experiment and optimize electrode materials. These fabrication lines enable precise control over the electrode composition, thickness, and morphology, allowing scientists to explore new materials and evaluate their performance characteristics. By advancing material research, Coin Cell fabrication lines contribute to the development of high-performance batteries with improved energy density, cycle life, and stability.

Prototyping and Proof-of-Concept Studies:

Coin Cell fabrication lines serve as a valuable tool for prototyping and proof-of-concept studies. Researchers can use these lines to fabricate small-scale Coin Cells quickly, allowing for rapid evaluation of new designs, formulations, and manufacturing processes. This enables researchers to iterate and refine their concepts, leading to breakthroughs in battery technology and enhancing the overall efficiency of the development process.

Performance Evaluation and Characterization:

Coin Cell small scale line are equipped with advanced testing and characterization capabilities. Researchers can evaluate the performance of Coin Cells under various conditions, including charge-discharge cycles, temperature extremes, and aging tests. This enables a thorough understanding of the battery's behavior and performance, providing valuable insights for further optimization and future development.

Scaling Up for Commercialization:

Coin Cell fabrication lines act as a stepping stone towards commercialization. The knowledge gained from research and development activities on the fabrication line can be applied to scale up production processes for mass manufacturing. This includes optimizing production parameters, streamlining quality control measures, and ensuring the consistency and reliability of Coin Cell production. The successful transition from the fabrication line to large-scale manufacturing is essential for bringing innovative battery technologies to market.

Collaboration and Knowledge Exchange:

Coin Cell fabrication lines foster collaboration and knowledge exchange among researchers, scientists, and industry experts. These lines often serve as shared facilities, where multiple teams can work together, share ideas, and benefit from cross-disciplinary expertise. The collaborative environment nurtured by Coin Cell fabrication lines accelerates the pace of innovation, encourages the exploration of new ideas, and facilitates the exchange of best practices.

Conclusion:

Coin Cell fabrication lines are instrumental in advancing research and development in the field of energy storage. They provide a platform for material exploration, prototyping, performance evaluation, and scaling up for commercialization. Through these lines, researchers can push the boundaries of battery technology, leading to improvements in energy density, safety, and efficiency. The collaborative and knowledge-sharing environment fostered by Coin Cell fabrication lines drives innovation and accelerates the development of next-generation batteries. As we continue to strive for more efficient and sustainable energy storage solutions, the significance of Coin Cell fabrication lines in research and development cannot be underestimated.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915