- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

- 2023-07-07

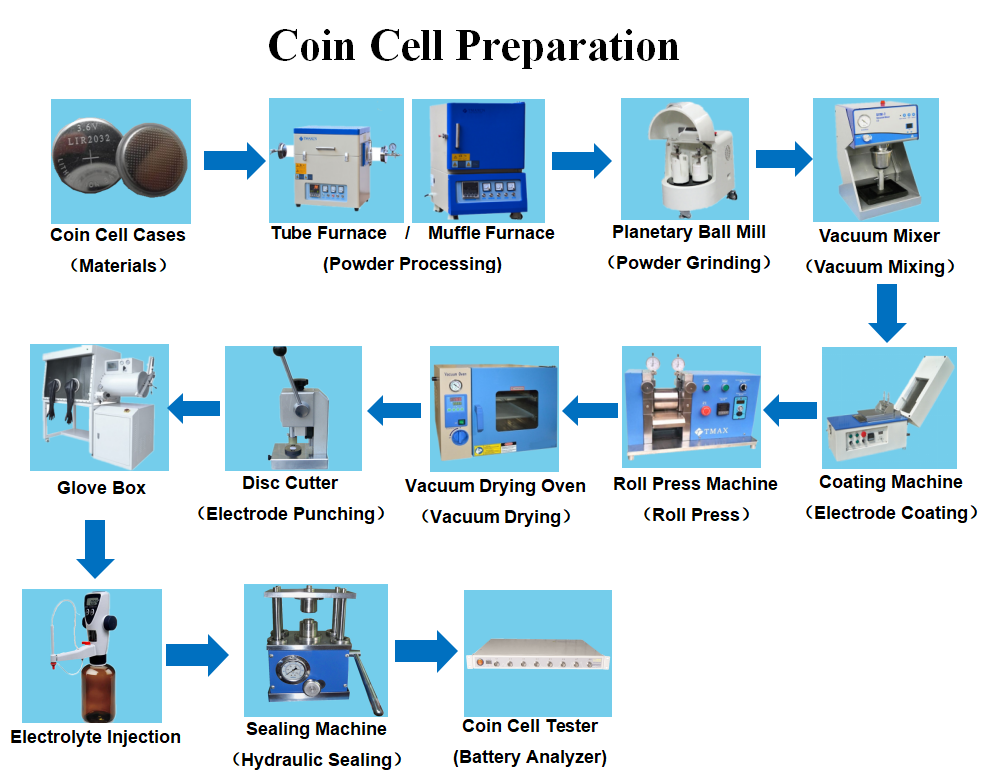

Coin Cell fabrication machine refers to the machinery, tools, and instruments used in the manufacturing process of coin cells, which are small cylindrical or button-shaped batteries commonly used in various electronic devices. This equipment is specifically designed to automate and streamline the production of coin cells, ensuring precise electrode placement, material deposition, and assembly.

Button Cell fabrication line includes various machines and devices, such as:

Electrode punching Machine: This machine is used to cut electrodes into precise sizes and shapes required for coin cell production.

Electrode Stacker : It is responsible for accurately stacking the positive and negative electrodes with separators to create the electrode assembly.

Coin Cell Crimper : This machine seals the electrode assembly within the coin cell casing to prevent leakage and ensure the integrity of the cell.

Electrolyte Filling Machine: It is used to inject the electrolyte solution into the sealed coin cell, which is necessary for its proper functioning.

Coin Cell Testing Equipment: This includes various testing instruments, such as voltage and capacity analyzers, impedance analyzers, and leakage testers, to assess the performance and quality of the fabricated coin cells.

Assembly Line Conveyors and Robotics: These equipment facilitate the smooth movement of coin cells through different stages of the fabrication process, ensuring efficient production and minimizing manual handling.

Coin Cell lab plant is designed to enhance the precision, consistency, and efficiency of the manufacturing process, leading to the production of high-quality and reliable coin cells. It plays a crucial role in the mass production of coin cells, enabling manufacturers to meet market demands effectively and deliver batteries that meet the required specifications and performance criteria.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915