- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

blog

Battery Assembly Plant

- 2024-07-09

Building a Battery Assembly Plant: A Comprehensive Guide

Establishing a battery assembly plant is a multifaceted process that involves careful planning, precise execution, and ongoing management. This guide provides an in-depth look at the essential stages and considerations necessary for building a successful battery assembly plant.

1. Planning and Feasibility Study

Market Analysis

-Demand Forecast**: Analyze the market demand for different types of batteries, including lithium-ion, lead-acid, and nickel-metal hydride. Identify the primary applications (e.g., electric vehicles, consumer electronics, energy storage systems).

-Competition Analysis**: Study the competitive landscape, including the production capacities, market shares, and technological advancements of existing players.

Financial Planning

-Investment Estimation**: Calculate the total investment required, encompassing land acquisition, construction, machinery, and working capital.

-Funding Sources**: Identify potential funding sources, such as loans, investors, government grants, or partnerships.

Site Selection

-Location**: Choose a strategic location with access to essential infrastructure like transportation, utilities, and skilled labor.

-Infrastructure**: Ensure the site has reliable access to electricity, water, gas, and waste disposal facilities.

2. Plant Design and Layout

Design Requirements

-Production Capacity**: Determine the desired production capacity based on market demand and scalability considerations.

-Space Planning**: Design the layout to optimize workflow efficiency, minimizing material handling and maximizing space utilization.

Layout Planning

-Raw Material Storage**: Allocate space for storing raw materials, including electrodes, electrolytes, separators, and casings.

-Production Lines**: Designate separate areas for each stage of production: electrode preparation, cell assembly, electrolyte filling, sealing, and formation.

-Quality Control**: Establish laboratories and testing areas for quality control and R&D.

-Finished Goods Storage**: Plan for storage of finished batteries before shipment.

3. Equipment Procurement

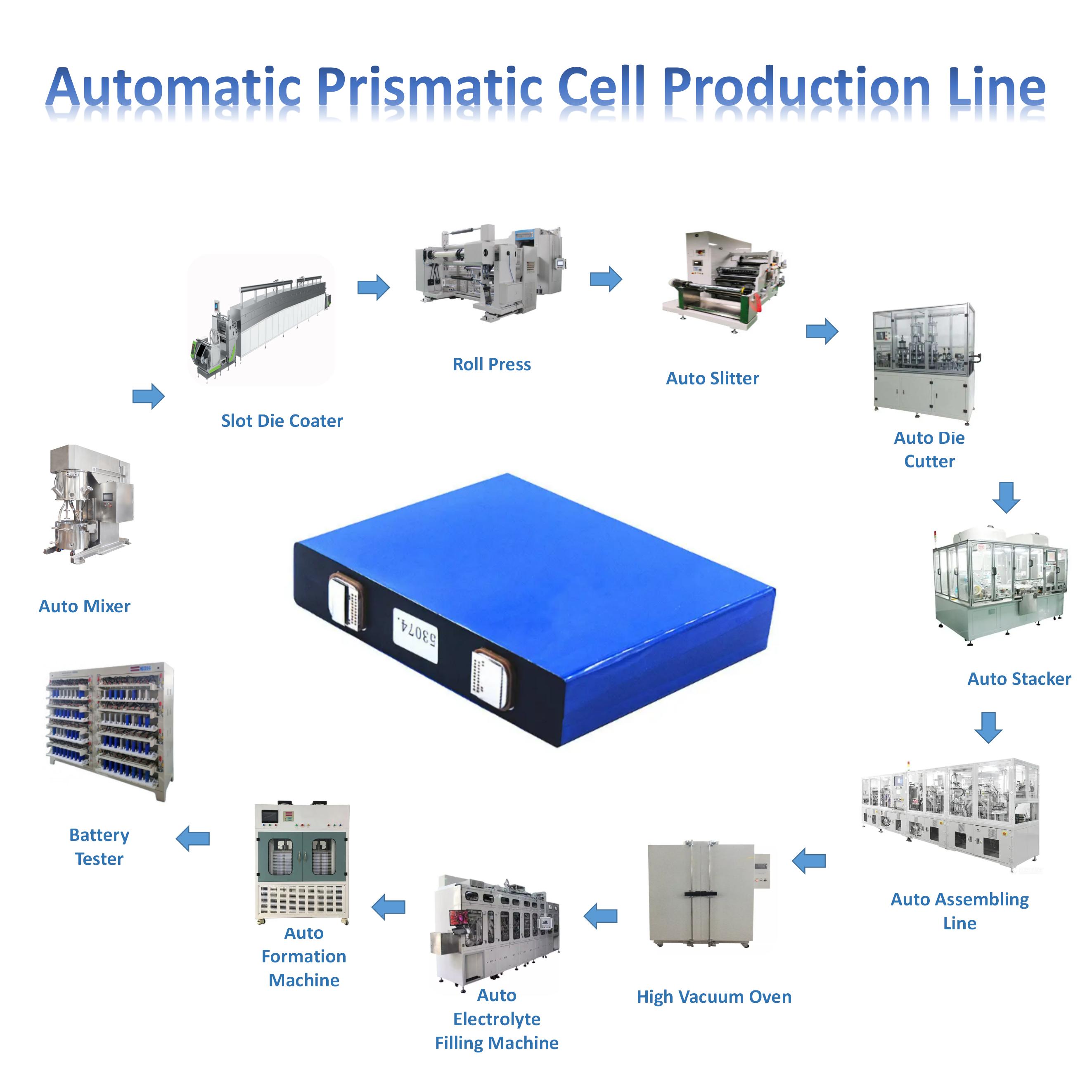

Key Equipment for EV Battery Assembly Plant

1. **Electrode Preparation Equipment**

-Mixers**: Prepare electrode slurry by mixing active materials, binders, and solvents. High-shear mixers ensure uniform consistency.

-Coating Machines**: Apply electrode slurry onto current collectors (aluminum for cathode, copper for anode). Precise control over thickness and uniformity is crucial.

-Drying Ovens**: Remove solvents from coated electrodes. Continuous or batch ovens can be used based on production scale.

-Calendering Machines**: Compress coated electrodes to the desired thickness and density, enhancing electrochemical performance.

-Slitting Machines**: Cut the dried and calendered electrodes into precise sizes for further processing.

2. **Cell Assembly Equipment**

-Cutting Machines**: Precisely cut separators to match electrode dimensions.

-Stacking/Winding Machines**: Assemble electrodes and separators into stacks (pouch and prismatic cells) or wound structures (cylindrical cells). Automation ensures consistency and precision.

-Tab Welding Machines**: Weld current collector tabs to electrodes. Ultrasonic or laser welding is commonly used for strong, reliable connections.

-Electrolyte Filling Machines**: Inject electrolyte into assembled cells. Precision filling is essential for optimal cell performance and safety.

-Sealing Machines**: Seal the cells using methods like heat sealing, ultrasonic sealing, or laser welding, depending on the cell type (pouch, cylindrical, prismatic).

3. **Formation and Testing Equipment**

-Formation Equipment**: Perform initial charge/discharge cycles to form the solid electrolyte interface (SEI) on the anode and stabilize cell performance.

-Cyclers and Testers**: Test cells for capacity, voltage, internal resistance, and other key performance metrics. Automated systems can handle large volumes of cells.

-Environmental Chambers**: Simulate various operating conditions (temperature, humidity) to test cell performance and durability.

4. **Safety and Environmental Equipment**

-Fume Hoods and Scrubbers**: Control emissions from solvents and chemicals used in electrode preparation and cell assembly.

-Waste Management Systems**: Handle and dispose of hazardous waste materials safely and in compliance with regulations.

Vendor Selection

1. **Reputation and Experience**

- Choose vendors with a proven track record in the battery manufacturing industry.

- Check references and case studies of previous installations to ensure reliability and performance.

2. **Technical Support and Training**

- Ensure vendors provide comprehensive training for operating and maintaining equipment.

- Opt for suppliers who offer robust after-sales support, including spare parts availability and technical assistance.

3. **Customization and Flexibility**

- Vendors should be willing to customize equipment to meet specific production requirements.

- Equipment should be adaptable to future changes in battery technology and production processes.

4. **Quality and Certification**

- Ensure equipment meets industry standards and certifications (e.g., CE, ISO).

- Conduct factory acceptance tests (FAT) and site acceptance tests (SAT) to verify equipment performance before final acceptance.

Procurement Process

1. **Specification Development**

- Clearly define equipment specifications based on production needs, including capacity, precision, and compatibility with other systems.

- Consult with technical experts and engineers to ensure all requirements are covered.

2. **Request for Proposal (RFP)**

- Issue RFPs to multiple vendors outlining detailed specifications, project timelines, and budget constraints.

- Evaluate proposals based on technical compliance, cost, delivery time, and vendor reputation.

3. **Evaluation and Selection**

- Create a cross-functional team (engineering, procurement, production) to evaluate proposals.

- Conduct site visits and technical discussions with shortlisted vendors to clarify any doubts and ensure alignment with requirements.

4. **Contract Negotiation**

- Negotiate terms and conditions, including payment schedules, delivery timelines, warranties, and service agreements.

- Ensure clear clauses on performance guarantees, penalties for delays, and responsibilities for installation and commissioning.

5. **Installation and Commissioning**

- Coordinate closely with vendors during the installation phase to ensure proper setup and integration of equipment.

- Perform rigorous testing and calibration to verify equipment performance and compliance with specifications.

- Provide comprehensive training to operators and maintenance staff.

Conclusion

Procuring the right equipment for a Energy Storage Battery Assembly is a complex but critical process that involves careful planning, vendor selection, and technical evaluation. By following a structured procurement process and considering key factors such as equipment specifications, vendor reputation, and support services, businesses can ensure that their battery assembly plant is equipped with reliable, high-performance machinery. This, in turn, will enable efficient production, high-quality output, and scalability to meet future market demands.

Establishing a battery assembly plant is a multifaceted process that involves careful planning, precise execution, and ongoing management. This guide provides an in-depth look at the essential stages and considerations necessary for building a successful battery assembly plant.

1. Planning and Feasibility Study

Market Analysis

-Demand Forecast**: Analyze the market demand for different types of batteries, including lithium-ion, lead-acid, and nickel-metal hydride. Identify the primary applications (e.g., electric vehicles, consumer electronics, energy storage systems).

-Competition Analysis**: Study the competitive landscape, including the production capacities, market shares, and technological advancements of existing players.

Financial Planning

-Investment Estimation**: Calculate the total investment required, encompassing land acquisition, construction, machinery, and working capital.

-Funding Sources**: Identify potential funding sources, such as loans, investors, government grants, or partnerships.

Site Selection

-Location**: Choose a strategic location with access to essential infrastructure like transportation, utilities, and skilled labor.

-Infrastructure**: Ensure the site has reliable access to electricity, water, gas, and waste disposal facilities.

2. Plant Design and Layout

Design Requirements

-Production Capacity**: Determine the desired production capacity based on market demand and scalability considerations.

-Space Planning**: Design the layout to optimize workflow efficiency, minimizing material handling and maximizing space utilization.

Layout Planning

-Raw Material Storage**: Allocate space for storing raw materials, including electrodes, electrolytes, separators, and casings.

-Production Lines**: Designate separate areas for each stage of production: electrode preparation, cell assembly, electrolyte filling, sealing, and formation.

-Quality Control**: Establish laboratories and testing areas for quality control and R&D.

-Finished Goods Storage**: Plan for storage of finished batteries before shipment.

3. Equipment Procurement

Key Equipment for EV Battery Assembly Plant

1. **Electrode Preparation Equipment**

-Mixers**: Prepare electrode slurry by mixing active materials, binders, and solvents. High-shear mixers ensure uniform consistency.

-Coating Machines**: Apply electrode slurry onto current collectors (aluminum for cathode, copper for anode). Precise control over thickness and uniformity is crucial.

-Drying Ovens**: Remove solvents from coated electrodes. Continuous or batch ovens can be used based on production scale.

-Calendering Machines**: Compress coated electrodes to the desired thickness and density, enhancing electrochemical performance.

-Slitting Machines**: Cut the dried and calendered electrodes into precise sizes for further processing.

2. **Cell Assembly Equipment**

-Cutting Machines**: Precisely cut separators to match electrode dimensions.

-Stacking/Winding Machines**: Assemble electrodes and separators into stacks (pouch and prismatic cells) or wound structures (cylindrical cells). Automation ensures consistency and precision.

-Tab Welding Machines**: Weld current collector tabs to electrodes. Ultrasonic or laser welding is commonly used for strong, reliable connections.

-Electrolyte Filling Machines**: Inject electrolyte into assembled cells. Precision filling is essential for optimal cell performance and safety.

-Sealing Machines**: Seal the cells using methods like heat sealing, ultrasonic sealing, or laser welding, depending on the cell type (pouch, cylindrical, prismatic).

3. **Formation and Testing Equipment**

-Formation Equipment**: Perform initial charge/discharge cycles to form the solid electrolyte interface (SEI) on the anode and stabilize cell performance.

-Cyclers and Testers**: Test cells for capacity, voltage, internal resistance, and other key performance metrics. Automated systems can handle large volumes of cells.

-Environmental Chambers**: Simulate various operating conditions (temperature, humidity) to test cell performance and durability.

4. **Safety and Environmental Equipment**

-Fume Hoods and Scrubbers**: Control emissions from solvents and chemicals used in electrode preparation and cell assembly.

-Waste Management Systems**: Handle and dispose of hazardous waste materials safely and in compliance with regulations.

Vendor Selection

1. **Reputation and Experience**

- Choose vendors with a proven track record in the battery manufacturing industry.

- Check references and case studies of previous installations to ensure reliability and performance.

2. **Technical Support and Training**

- Ensure vendors provide comprehensive training for operating and maintaining equipment.

- Opt for suppliers who offer robust after-sales support, including spare parts availability and technical assistance.

3. **Customization and Flexibility**

- Vendors should be willing to customize equipment to meet specific production requirements.

- Equipment should be adaptable to future changes in battery technology and production processes.

4. **Quality and Certification**

- Ensure equipment meets industry standards and certifications (e.g., CE, ISO).

- Conduct factory acceptance tests (FAT) and site acceptance tests (SAT) to verify equipment performance before final acceptance.

Procurement Process

1. **Specification Development**

- Clearly define equipment specifications based on production needs, including capacity, precision, and compatibility with other systems.

- Consult with technical experts and engineers to ensure all requirements are covered.

2. **Request for Proposal (RFP)**

- Issue RFPs to multiple vendors outlining detailed specifications, project timelines, and budget constraints.

- Evaluate proposals based on technical compliance, cost, delivery time, and vendor reputation.

3. **Evaluation and Selection**

- Create a cross-functional team (engineering, procurement, production) to evaluate proposals.

- Conduct site visits and technical discussions with shortlisted vendors to clarify any doubts and ensure alignment with requirements.

4. **Contract Negotiation**

- Negotiate terms and conditions, including payment schedules, delivery timelines, warranties, and service agreements.

- Ensure clear clauses on performance guarantees, penalties for delays, and responsibilities for installation and commissioning.

5. **Installation and Commissioning**

- Coordinate closely with vendors during the installation phase to ensure proper setup and integration of equipment.

- Perform rigorous testing and calibration to verify equipment performance and compliance with specifications.

- Provide comprehensive training to operators and maintenance staff.

Conclusion

Procuring the right equipment for a Energy Storage Battery Assembly is a complex but critical process that involves careful planning, vendor selection, and technical evaluation. By following a structured procurement process and considering key factors such as equipment specifications, vendor reputation, and support services, businesses can ensure that their battery assembly plant is equipped with reliable, high-performance machinery. This, in turn, will enable efficient production, high-quality output, and scalability to meet future market demands.

HOT PRODUCTS

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915