- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

1700°C Vacuum Chamber Atmosphere Furnace for Silicon Carbide Heating Elements

Model Number:

TMAX-1700ChamberfurnCompliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

1700°C Vacuum Chamber Atmosphere Furnace for Silicon Carbide Heating Elements

Vacuum chamber atmosphere furnace for silicon carbide heating elements, USES the three layers of shell structure and the Japanese island of 40 program temperature control system, electric phase-shifting trigger, thyristor control, furnace using polycrystal line alumina fiber materials imported from Japan, equipped with air cooling system between internal and external bile, can rapid cooling.

Using shell overall sealing cover board and the oven door seal adopts high temperature silicone o-rings, oven door is equipped with water cooling system, gas after flowmeter by the breech, after furnace, gas outlet valve discharge by the door of the oven.

The furnace can be sintered in a vacuum. The furnace has a quick connector with KF25 on the side, which can be connected with vacuum pumps. The vacuum pump has a smoke filter and a suction nozzle with a dust filter.

With corrugated pipe, vacuum pump (connected to the furnace and vacuum tube), KF25 quick card sets, vacuum flapper valve, resistance vacuum gauge, etc., whereas the minimum vacuum degree is less than 5 pa, can also be hydrogen and argon, nitrogen, oxygen, carbon monoxide, protective gas such as ammonia decomposition gas, &energy-saving small size, low temperature field balancing, surface temperature and elevating temperature rate, energy saving, universities, research institutes, industrial and mining enterprises do protect the sintering atmosphere, reducing atmosphere with the ideal product.

The sealing of the furnace is made of glove box technology. The sealing effect is very good. It can be used in a vacuum or atmosphere, and it can ensure that the pressure gauge is not deflected within 5 hours.

1. Heating element

(1) the hot end roughness d of the silicon carbon rod is 14mm, the average factory adopts 12MM, the heating end is thick, the surface load of the rod is low, and the service life is long.

(2) the length of the cold end of m is 210mm. The average manufacturer adopts 180mm, and the cold end has a low temperature.

(3) the surface oxidation of the silicon carbide rod is compact and can better protect the carbon rod.

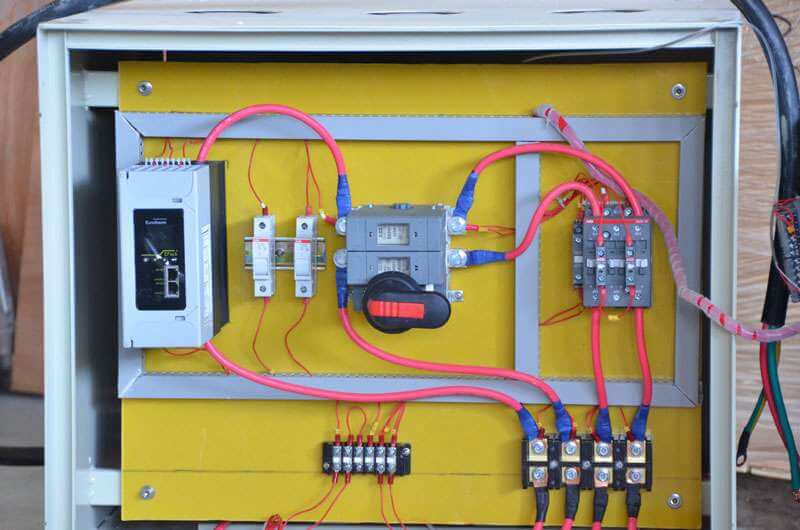

2. Install air switches and leakage protectors:

When an electric current or leakage, an empty meeting automatically disconnects.

3. Can connect with computer (Optional)

Furnace with communication interface and software, can be directly through the furnace computer control of each parameter, and can be observed from the computer PV on the stove and SV temperature and the running situation, the actual temperature of the furnace curve drawing computer real time, and can keep the temperature data of each time, can call up at any time

4. Chamber

Imported  VS

VS

Chinese

Chinese

1. High quality high pure alumina polycrystalline fiber cured furnace with vacuum suction and filter molding.

2. Adopt Japanese technology to form.

3. Low heat capacity and low heat conduction coefficient of furnace materials, resulting in less heat dissipation, good insulation and high reflectivity. Temperature equilibrium.

4. Long, high temperature and high resistance to heat and shrinkage of alumina filament.

5. The surface of the furnace is smooth and easy to remove powder.

6. Optional UL certified electrical board (all imported electrical appliances approved by UL)

|

Item No. |

TMAX-1700Chamberfurnace |

TMAX-1700Chamberfurnace |

|

Power |

7KW |

13KW |

|

Chamber size(mm) |

300X200X200 |

400X300X300 |

|

Overall meas.(mm) |

600X610X 1440 |

700X 700X1540 |

|

Voltage |

220V |

380V |

|

Phase |

Single |

Single |

|

Heating element |

Mosi2 |

|

|

Temperature controller |

40 programmable segments (Shimaden fp93 made in Japan), It can separate into 4,2,1 programs, ie. 4x10 segments. FP93 have 6 PID controls, different PID are used for low,middle, high temperature for precise control. Over-temperature and over-current protection, shutdown automatically when thermocouple is broken ( it will shut down power when temperature is higher than 1620⁰or thermocouples is broken, "ON" on the board is off and "OFF" is on) There is Fahrenheit (F) and Celsius (C) for option. With 485 communication interface: which can stop the furnace automatically.

|

|

|

Chamber |

1800 Polycrystalline alumina fibre. Imported from Japan |

|

|

Temperature Accuracy |

+/- 1 ℃ |

|

|

Trigger |

Phase-shift trigger |

|

|

Power control |

Chint |

|

|

Controlled silicon |

Germany Semikron 106/16E |

|

|

Max. Temperature |

1700 ℃ |

|

|

Constant temperature |

1650 ℃ |

|

|

Max. Vacuum Temperature |

1500℃ |

|

|

Vacuum level in cold |

≤10Pa |

|

|

Heating Rate |

≤20 ℃/ Min |

|

|

Recommended Heating Rate |

≤10 ℃/ Min |

|

|

Thermocouple |

Type B |

|

|

Surface temperature |

≤45℃ |

|

|

Vacuum pump |

VRD-16

|

|

|

Air switch |

|

|

|

Certificate |

CE Certificate |

|

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915