- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

1200°C Vacuum Hot Pressing Furnace with Resistance Wire Canthal A1 (Sweden)

Model Number:

TMAX-Press-Furnace1Dimension(L*W*H):

900X600X1600 (WXDXH)Compliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportDelivery Time:

3 Days

Wechat:13506084915

1200°C Vacuum Hot Pressing Furnace with Resistance Wire Canthal A1 (Sweden)

TMAX-Press Furnace1 the vacuum hot-pressing furnace by vacuum tube furnace, 40 t electric compressor, quartz vacuum cavity, 1/2 inch of graphite mould, tube furnace with resistance wire Canthal A1 (Sweden) as the heating element, using double shell structure and 30 program temperature control system, phase shift trigger, thyristor control, furnace adopts polycrystalline alumina fiber materials, the hot-pressing furnace is mainly used in the preparation of dense composite materials under high pressure in a vacuum.

Software control system (choose) : this furnace is equipped with communication interface and software, can be directly through the furnace computer control of each parameter, and can be observed from the computer PV on the stove and SV temperature and the running situation, the actual temperature of the furnace curve drawing computer real time, and can keep the temperature data of each time, can call up at any time.

Open cover protection system: the furnace is equipped with a travel switch. When the cover is opened, it will automatically cut off the power and ensure the user's safety.

Sealing system: the furnace tube and flanges are sealed with silicone o-ring, easy to remove, retractable, good air tightness, and ensure that the pressure gauge of 12 hours is not deflected.

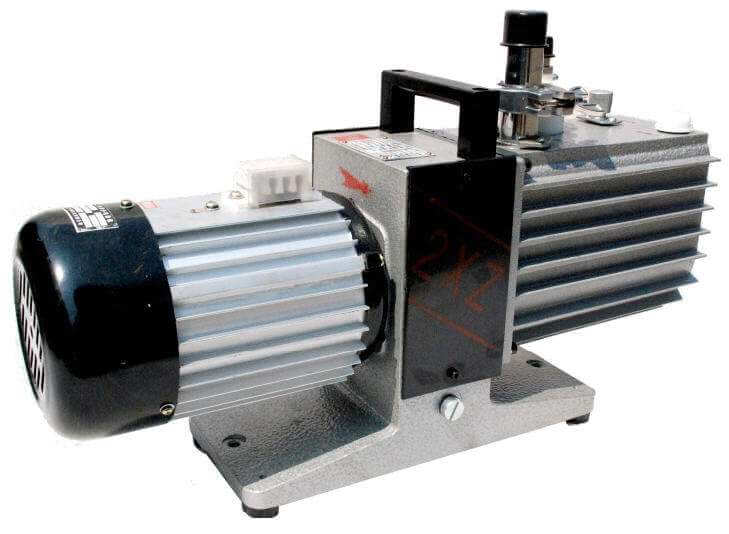

Vacuum system (optional) : can be equipped with tw-1.5 A vacuum pump and can be pumped to 10-1pa vacuum pump or can be pumped to 10-4Pa German imported molecular pump.

Furnace material: adopt Japan imported furnace material, not drop powder, material heat preservation performance good, reflectance high, temperature field balance, anti - heat gain cold - shrinkage ability.

Heating element: using the world top resistance wire of Sweden Canthal A1 resistance wire using long, temperature field equalization.

Contyre wire data download

Leakage protection function: the furnace is equipped with a leaky air switch to ensure the safety of use when the furnace leaks power.

Characteristics of hot-pressing furnace:

(1) the equipment can combine extrusion and sintering into a process to achieve high density and high strength composite materials.

(2) open type vertical heating body, furnace tube flange can coil out of the shaft.

|

Model |

TMAX-PressFurnace1 |

|

Power |

3.5 KW |

|

Chamber size(mm) |

Dia100 (OD) X700 |

|

boundary dimension |

900X600X1600 (WXDXH) |

|

supply voltage |

110V/220V |

|

Phase |

Single |

|

Heating element |

Sweden Kanthal A1 resistance

wire

Sweden resistance wire VS Chinese resistance wire |

|

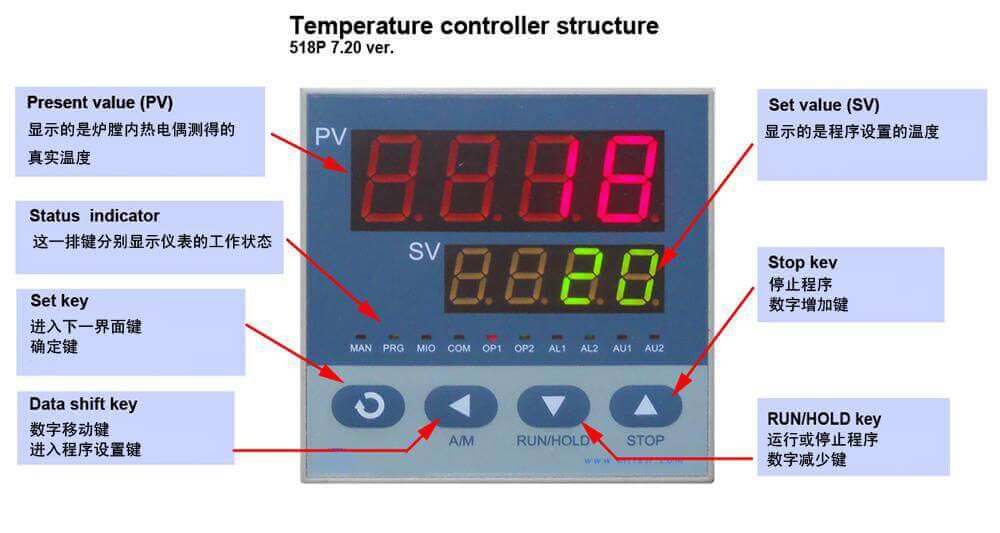

Temp Control Mode |

Adopt the yu electric program control thermometer

1.The 30 program control temperature can only adjust PID. 2.over temperature protection is broken accidentally protection with a temperature or broken accidentally electric furnace heating circuit automatically cut OFF, and, when the temperature of the furnace more than 1200 degrees or thermocouple burn out, the main circuit of ac relay will automatically disconnect, main circuit disconnect, panel ON lights, OFF the light, the limited protection electric furnace). 3. With 485 communication interface (standard and standard for choosing software) 4. It has the function of power failure protection, that is, when the power is off, the program will not start up from the beginning temperature, but the furnace will start to rise when the power is off. The instrument has the function of temperature self-setting

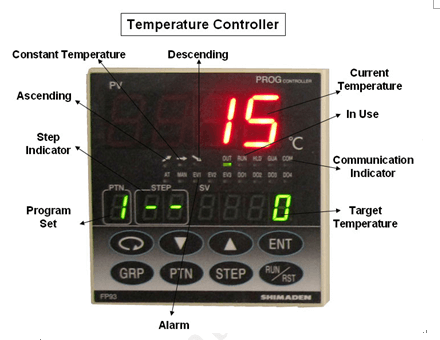

FP93 temperature controller(SHIMADEN,Japan)(optional)

1. The program control temperature can be divided into 4, 2 and 1 groups. If it is divided into 4 groups, each program is 10 paragraphs. 2. The PID control of group 6, low, medium and high temperature can be used with a set of PID, so that each temperature segment can be controlled accurately. 3. over temperature protection is broken accidentally protection with a temperature or broken accidentally electric furnace heating circuit automatically cut OFF, and, when the temperature of the furnace more than 1200 degrees or thermocouple burn out, the main circuit of ac relay will automatically disconnect, main circuit disconnect, panel ON lights, OFF the light, the limited protection electric furnace). 4. The meter has the degree of Fahrenheit (F) and Celsius (C) 5. With a 485 communication interface (with the selection of software) 6. Automatic stop function 7. You can store multiple sets of programs and use them in any way you want. 8. It has the function of power failure protection, that is, when the power is off, the program does not start up from the beginning temperature, but the furnace temperature starts to rise from the power failure. 9. The instrument has output power, the number of segments and the execution time of the program, the display of temperature, temperature and cooling status of the program. 10. The meter has the function of skipping (that is, the meter can jump this step and carry out the next step directly. 11. The instrument has the function of temperature self-tuning.

|

|

Chamber materiels |

Alumina polycrystalline fiber (more than 95% aluminum oxide content) imported from Japan

Imported VS Chinese |

|

control precision |

+/- 1 ℃ |

|

trigger |

Phase-shifted trigger |

|

electric appliance |

Zhejiang zhengtai |

|

silicon controlled |

106/16E SEMIKRON, Germany |

|

maximum temperature |

1200 ℃ |

|

rated temperature |

1150 ℃ |

|

heating rate |

≤30 ℃/ Min (Modify as required) |

|

Recommended heating rate |

≤15 ℃/ Min |

|

Thermocouple Type |

K |

|

heating-length |

300mm |

|

SHIMADEN FP93 controller and software |

COM and USB switcher Dataline of computer and furnace |

|

vacuum system |

TW-1.5A 2XZ-2 VS-0.1 VS high vacuum system Generally, the gas in the tube is made out of A rough vacuum 2. 2xz-2 vacuum pump can pump the vacuum of tube furnace tube to about 10Pa 3. The vs-0.1 vacuum system can pump out the vacuum in tube furnace tube to 0.1 Pa (with resistance vacuum gauge display) 4. VS high vacuum system (which is composed of molecules and mechanical pumps) can vacuum the tube furnace tube to 10-3 Pa. |

|

mould |

1. High temperature mould unit is made of high purity graphite and the maximum working pressure is 50MPa 2. Please carefully design the dimensions of the high temperature mold and select the correct pressure. |

|

dwell time |

0-50Min |

|

pressure stroke |

40mm |

|

pressure stability |

≤1MPa/5min |

|

maximum pressure |

6T(The pressure gauge shows 10MPa) |

|

water-cooling(Optional) |

water-cooling machine |

|

Certification |

CE |

|

Surrounding surface temperature |

≤45℃ |

|

safety system |

There are air switches and fuses on the furnace, and

when the current exceeds the rated current of the air, the empty meeting

automatically jumps open and effectively protects the furnace. |

|

Switching protection system |

The furnace is equipped with a travel switch. When the cover is opened, the relay will automatically cut off the main power supply and ensure the user's safety. |

1. We supply machines with battery technology support.

2. We supply full set of lithium battery equipment for lab research, pilot scale research and production line.

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915