- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

Versatile Roll to Roll Film Coating Machine

Model Number:

TMAX-AFA-MC400Dimension(L*W*H):

L6800mm x W1200mm x H1900mm Can be customizedCompliance:

CE CertifiedWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

Versatile Roll to Roll Film Coating Machine

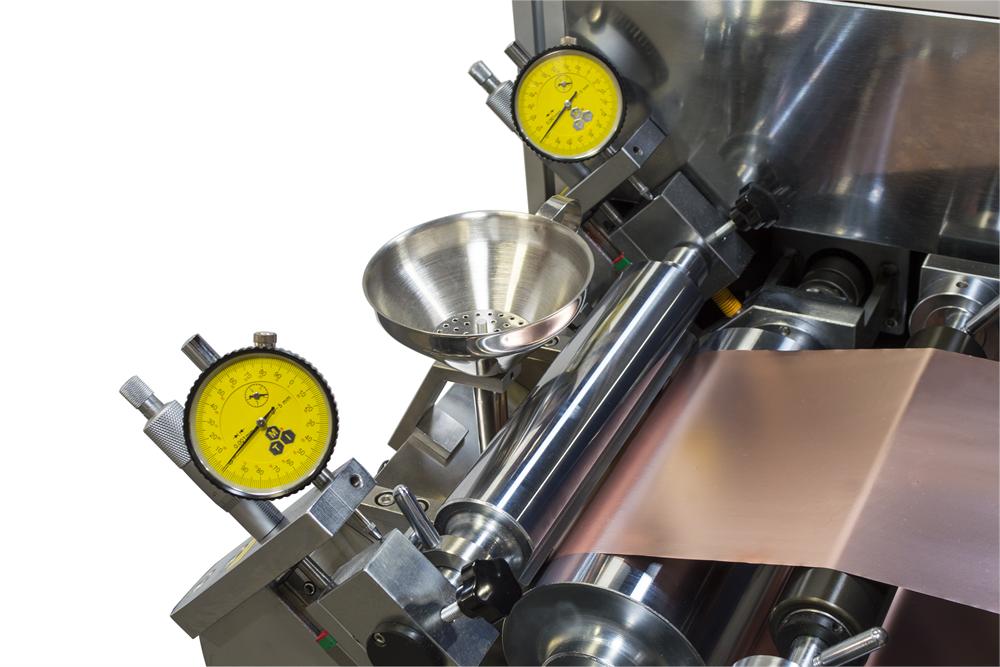

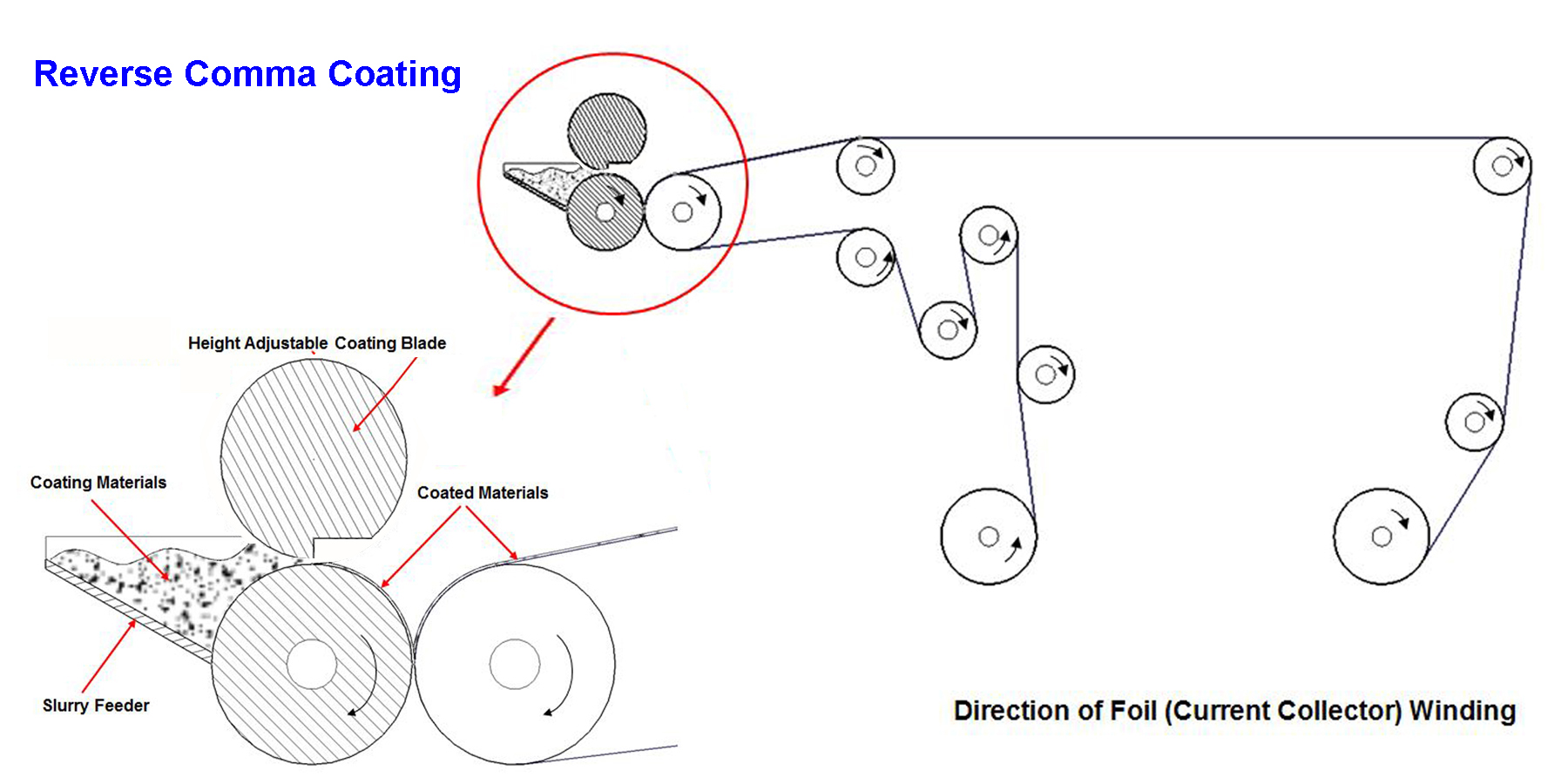

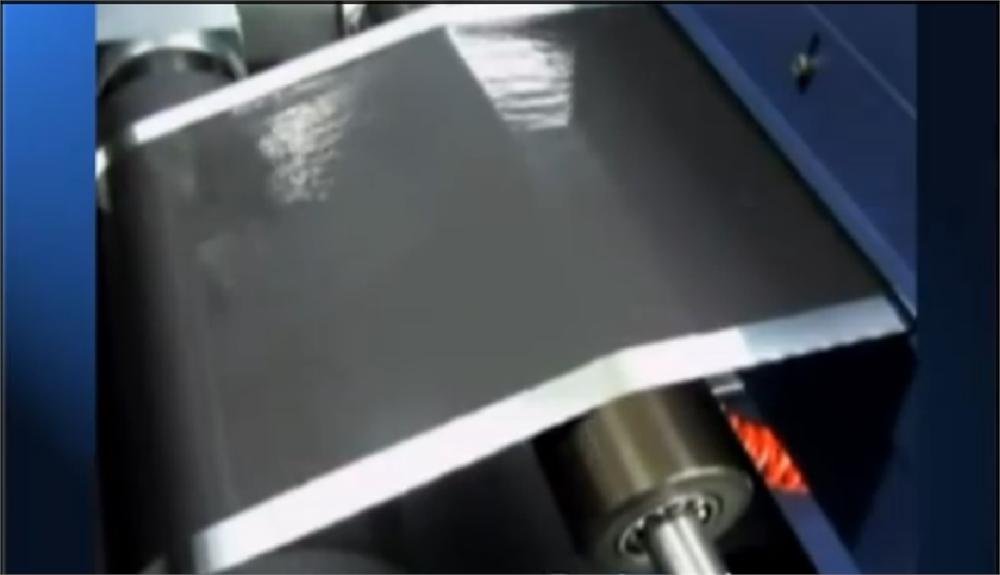

TMAX-AFA-MC400 is a versatile roll to roll coating system which can adapt various coating heads such as reverse comma blade, Doctor Blade, Slot Die and Micro Gravure and Tape Casting. A 4.5 meters long, three zone convection drying oven with independent temperature programming is implemented for efficient slurry curing. This is the most complete and universal pilot coating system that provides a broad adaptability to various coating slurries and film substrates (Cu, Al, PET, PP, PE).

- Doctor Blade: Cost effective solution for 8~200 micron thick coatings (Continuous mode only)

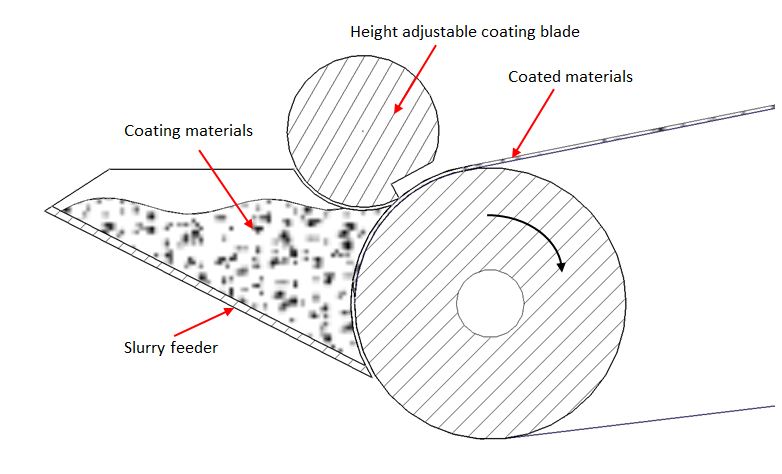

- Reverse Comma Blade (Transfer Coating): Cost effective solution for 30~200 micron thick coatings (Both continuous & intermittence mode)

- Tape Cast Coating: Ideal for performing thicker coating up to 1000 microns with high viscosity slurry

- Micro-Gravure: Perfectly suitable for precise thin coatings from 1~3 microns (dry film thickness)

- Slot Die: Suitable for precision coatings as thin as 1 micron while providing a wide coverage for thicker coatings upto 200 microns

Specifications:

|

Working Voltage |

110 - 240 VAC, 50/60 Hz, three Phase (380VAC three phase is available upon request) |

|

|

Max. Power Consumption |

30-35 KW ( 50A Air breaker required ) |

|

|

Compressed Air |

0.5-0.9 MPa is required (Air compressor not included.

|

|

|

Reeling/Unreeling Diameter |

|

|

|

Coating Width |

350mm Max. |

|

|

Coating Speed |

Max.5000mm/min |

|

|

Coating Heads

|

Doctor Blade Coating |

|

|

Reverse Comma Blade (Transfer Coating) |

|

|

|

Cast Coating |

|

|

|

Slot Die coating |

Attention: The final coating thickness is dependent on a wide range of parameters such as slurry viscosity, solid particle size, solid content, shim thickness, foil rolling speed and slurry feeding rate. Therefore, we are not able to guarantee that 1-micron level film is achievable for all kinds of slurries. For further discussion, please let us know your slurry specs and coating thickness requirement. |

|

|

Micro-Gravure Coating |

|

|

|

Convection Drying Oven |

|

|

|

Product Dimensions |

L6800mm x W1200mm x H1900mm |

|

|

Compliance |

|

|

|

Warranty |

|

|

|

Application Notes |

|

|

|

Net Weight |

13t |

|

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915