- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

Surface Area and Porosity Analyzer

Model Number:

TMAX-X1000Compliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

Surface Area and Porosity Analyzer

Features:

1. Multiple parallel analysis ports and ultramicropore analysis

2. Ultrahigh vacuum bistable solenoid valves and gas circuit with integrated manifold

3. A two-way, multichannel PFC and high-accuracy pressure electronic control system

4. High-stability system temperature control

5. Direct connection of sensor with sample compartment

6. Independent dryer and in-situ drying of analysis ports

7. Built-in computer system with a LCD touch screen

8. Self-regulation of dynamic Gas injection volume and dynamic equilibrium time

9. Ultra long analysis time and liquid nitrogen depletion protection

10. Breakpoint preservation and network remote control function

11. Strong but lightweight Mn/Al alloy skeleton and various color schemes

12. High-quality accessories and multiple options

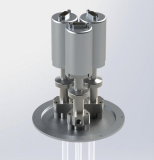

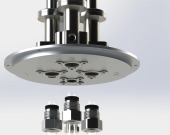

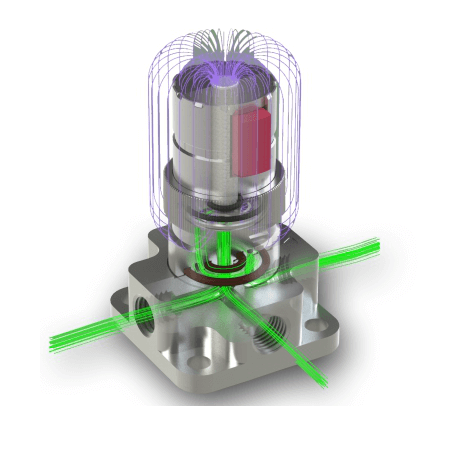

Multiple parallel analysis ports and ultramicropore analysis

TMAX-X1000 Series Adsorption Analyzers configured with multiple parallel analysis ports can analyze 1-3 samples at the same time. In order to meet the requirements of researcher customers, each analysis port is equipped with ultra-low pressure sensors, which can provide high-precision analysis for macropore, mesopore, micropore and ultramicropore.

1. Shortest connection of analysis port with pressure sensor avoids pressure gradient deviations caused by long distance between the sample compatment sensor.

2. Embedded connection mode of analysis ports visualizes and simplifies the installation process.

3. Ultra-low pressure sensors make ultramicropore analysis possible.

Built-in computer system

TMAX-X1000 Adsorption Analyzer has an independent built-in computer system with a 10.2-inch chromatic LCD touch screen and a more than 32GB flash memory to store user data. LAN interface provides remote control and data download functions for users. A standard USB2.0 interface allows the use of expansion devices such as keyboard and USB flash drive. Breakpoint preservation function allows interrupt occurrences during analysis process.

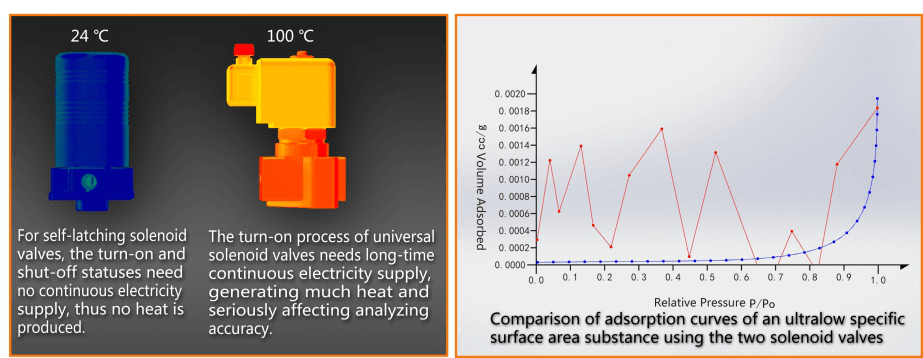

Ultrahigh vacuum self-latching solenoid valves

In adsorption analyzing fields, the heating problem in universal solenoid valves has existed for a long time, which seriously affects accuracy of gasometry and pressure reading, especially in the process of analyzing ultra-small specific surface area and micropores. Aiming at solving the problem, our company developed a new solenoid valve with self-latching ability. It can keep on/off status without continuous electricity supply. Calorific value is equivalent to zero. TMAX-X1000 Series Adsorption Analyzers adopt self-latching solenoid valves and its analyzing

performance has been substantially improved.

The adsorption curve of an ultralow specific surface area substance (blue) achieved by using self-latching solenoid valves is precise and balanced, while for adsorption curve using universal solenoid valves, the test results are invalid data points.

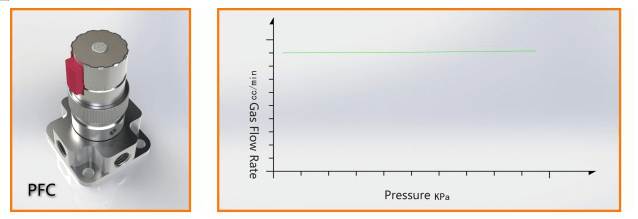

PFC high-accuracy multichannel pressure electronic control system

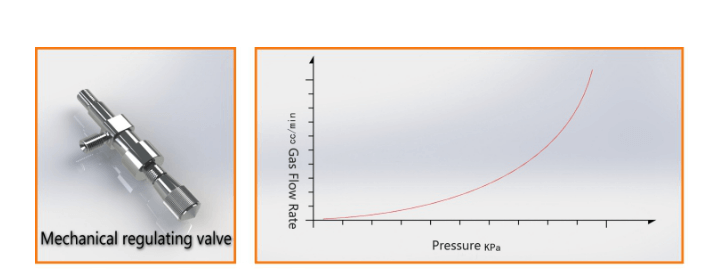

PFC pressure and flow rate controller designed and developed by our company is dedicated to TMAX-X1000 Series instruments. It is a two-way, multichannel and high-accuracy pressure electronic control valve, which provides reliable guarantee for rapid gas injection volume and stable air pumping, voiding various weaknesses of mechanical metering valves.

Automatic cintrol of PFCcan obtain rapid and constand gas flow rate

Flow rate in mechanical regulating valves changes as a function of gass pressure.

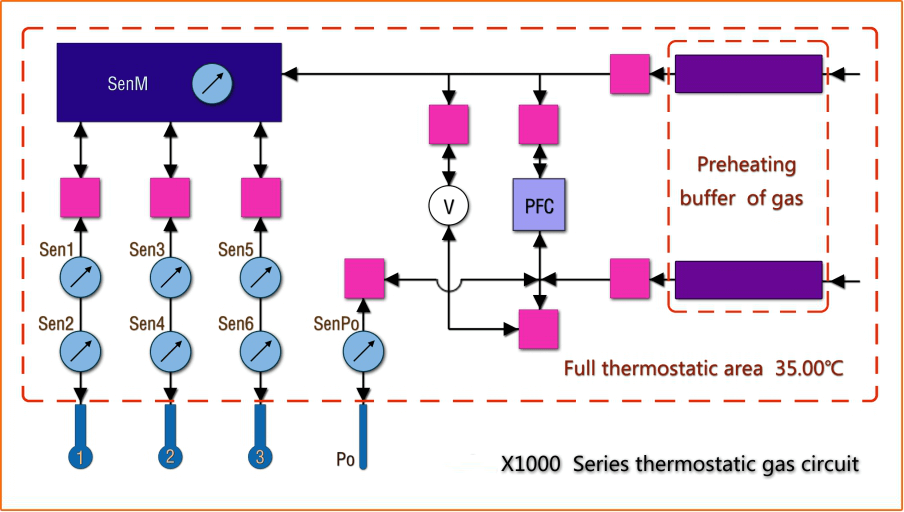

Highly stable system temperature control

Physical adsorption analyzer based on gas volumetric method determines adsorbing capacity by measuring pressure changes using pressure sensors. The accuracy and valid resolution are extremely sensitive to temperature changes, especially in the process of analyzing micropores and ultralow specific surfaces. Temperature changes can not only affect the computing accuracy of adsorbing capacity, but also lead to zero drifts in pressure sensor, causing relatively larger deviation of calculated micropore size. Therefore, a constant temperature is of great importance to high-accuracy analysis. TMAX-X1000 Adsorption Analyzer avoided analytical error caused by environmental temperature changes by adopting high-accuracy and high-stability full thermostatic control in gas circuit system.

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915