- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

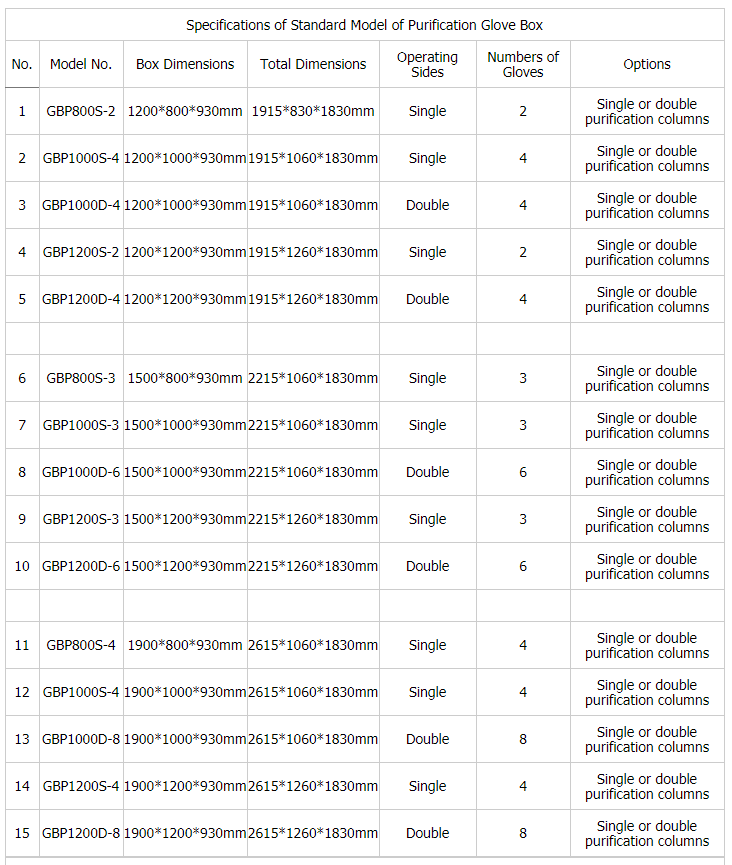

Stainless Steel Vacuum Glove Box with Automatic Regeneration and Pressure Control

Model Number:

TMAX-VGB-6Dimension(L*W*H):

Length: 1220mm (48.0”) Depth: 750mm (29.5”)Compliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

Stainless Steel Vacuum Glove Box with Automatic Regeneration and Pressure Control

Features

Closed Loop Gas Circulation

Inert gas in a closed loop. The gas is circulated by the blower and purifier, H2O, O2 can be removed continuously.

Auto Purging

The replacement of the atmosphere inside the glove box can be achieved automatically by the purging valves.

Automatic Regeneration

H2O and O2 removal material can be regenerated. The regeneration process can be program controlled.

Automatic Pressure Control

The pressure in the glove box is controlled automatically by the Programmable Logic Controller (PLC). Working pressure can be set between +10mba and -10mba. If the pressure goes over+/- 12mbar, the system will be protected automatically.

Eco Mode

The vacuum pump will be activated automatically when necessary, and will turn off after a period of idle time. Blower frequency will be switched to 25Hz when moisture and oxygen level reaches to less than 1 ppm

SPECIFICATIONS:

|

Model |

TMAX-VGB-6 |

|

Source voltage |

AC110V-240V, Customized |

|

Warranty |

Two Years limited warranty with lifetime support |

|

Type |

Single section single station |

|

Dimension(L*W*H) |

SUS304 stainless steel plate, 1200*800*930mm |

|

Total dimension(L*W*H) |

SUS304 stainless steel plate, 1915*830*1830mm |

|

Big transitive cabin |

SUS304 stainless steel, DN385*588mm |

|

Small transitive cabin |

SUS304 stainless steel, DN150*350mm |

|

Gloves |

2 pcs, butyl material, thickness : 0.4mm |

|

Gloves port |

DN215mm, Acid and alkali resistant material PPS |

|

Purification system |

Single purifying column, With the remove of water, oxygen function |

|

Control system |

6 inch color touch screen, SIEMENS |

|

Vacuum pump |

4L/S |

|

Pressure sensor |

-2500~2500Pa, Touch screen |

|

H2O concentration |

<1 ppm (20 °C, 1 atm) Touch screen |

|

Oxygen concentration |

<1 ppm (20 °C, 1 atm) Touch screen |

|

Organic solvent filter |

21 L |

|

Working gas |

N2,Ar,He |

|

Notes: |

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915