- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

Model Selection Instruction for Vacuum Planetary Centrifugal Mixer

Model Number:

TMAX-TPCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

Model Selection Instruction for Vacuum Planetary Centrifugal Mixer

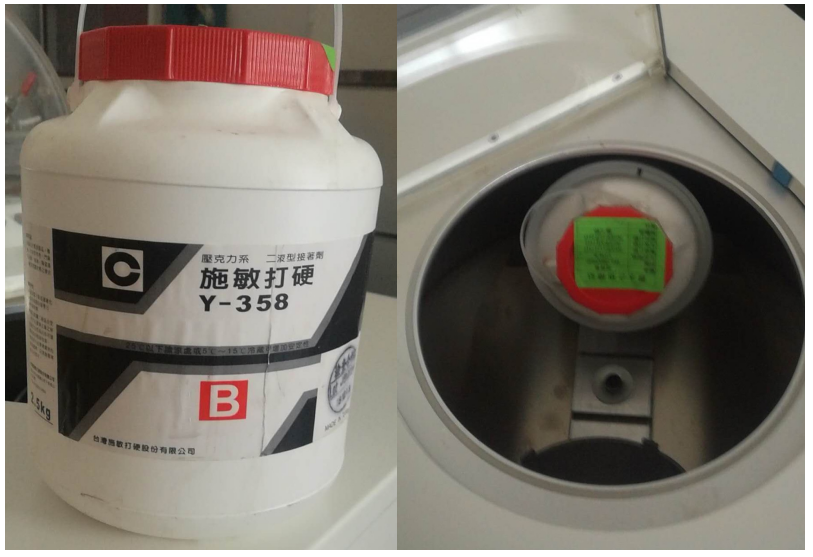

This machine is suitable for mixing, stirring and defoaming of conductive / resistive materials such as gold / silver / carbon paste, new polymer materials, sealing / insulating materials such as glass / ceramic paste, chemical paste, sealing materials / adhesives such as single and double liquid epoxy resin, LED fluorescent agent / silica gel and other molding materials. It can mix evenly without dead corner and separate nano bubbles from the materials. It is widely used in research institutes, university laboratories, new material research and production, LED lamp bead production, needle tube glue defoaming in electronic factory, and medical material research and development.

Our company's agitation defoamer after our engineers' careful design, in line with the customer's consideration, simple operation, easy to use, improve service life, reduce failure, modular design. The maintenance is simple, a few years later to change a few accessories can reach the new machine effect.

The comparison between revolution and rotation mixing mode and traditional mixing mode

1. Uniform mixing is achieved by rotating and rotating at the same time without stratification

2. The material is evenly dispersed by strong stirring with centrifugal gravity generated by revolution and rotation

3. Through high-intensity vacuum pumping, the nano bubbles in the mixture were removed, and the stirring force turned over

Rolling action, no matter how viscous the mixture is, it will be clean and free of nano bubbles

4. No spiral blade, no need to clean blade, no pollution of raw materials

5. No damage to material shape (fibrous material and powder)

6. The size and specification of the products are complete enough to cope with all aspects from research and experiment to production. The fixture of suitable container can be customized to meet the needs of different customer groups.

7. Suitable for mixing most materials. Especially for those materials with high viscosity, its efficiency can be greatly improved.

8. Human computer interaction mode, easy to use, extremely simple operation, no training, hands-on use.

Function of stirring and defoaming machine

Revolution efficiency: during revolution, the material is subjected to centrifugal force in the material cup, and the specific gravity separation movement along the vector direction and the upward pushing effect generated by the material's self weight separate the bubbles, and the material is extracted vigorously by the vacuum pump, and the separation is clean.

Rotation efficiency: the material rotates in the container at the same time, so that the material itself produces strong vortex fluidity, forming the effect of centrifugal vector synthetic force, the shear force between the material and the wall, and the interaction force between the molecules in the material, resulting in the mutual dispersion effect.

Our main configurations

Main shaft: using Swiss ASSAB S136 mirror mold steel, after multiple heat treatment, the overall hardness reaches HRC62. The shaft is ground as a whole, and the total run out is no more than 1 wire. The surface roughness of the sealing surface is 0.02um, the friction coefficient is very low, the wear of the sealing ring is very little, and the super long service life of the seal is achieved. This is one of the magic weapons for many of our customers to keep negative pressure above - 98kpa after several years of use.

Seal ring: the super wear-resistant seal ring made by Bayer company of Germany is adopted. The wear-resistant bearing capacity can reach 40m / s. The linear speed of our equipment is only 4m / s at 2000 rpm. The pressure can bear 20kg / C ㎡. This is the second magic weapon for many of our customers to keep negative pressure above - 98kpa after several years of use.

Vacuum pump: German technology small diamond vacuum pump, equipped with forced lubricating oil pump, fully lubricated, reliable performance, low noise, with our company's unique 4-stage filtration, to meet the requirements of the purification room.

Gear: adopt spiral bevel gear structure, material upgrade to super wear-resistant nylon, stable operation, low noise, long life.

Rotary arm: it adopts integral rotary arm, which is made of aviation magnesium aluminum 7075 imported from the United States. The accuracy and stability of the product are ensured, and the center error is not greater than ± 0.02. High interchangeability, the same type of machine arm into arbitrary exchange, easy maintenance. The transmission mechanism has long life and maintenance free.

Selectable models

|

Types |

Model |

Single cup volume |

Total volume |

|

Single-cup mixer (fixed rotation and revolution speed ratio) |

TMAX-TP-300 |

150ML |

150ML |

|

TMAX-TP-900 |

450ML |

450ML |

|

|

Two cup mixer (fixed rotation and revolution speed ratio) |

TMAX-TP-300S |

150ML |

300ML |

|

TMAX-TP-900S |

540ML |

1080ML |

|

|

TMAX-TP-1500S |

1000ML |

2000ML |

|

|

TMAX-TP-4000S |

2400ML |

4800ML |

|

|

TMAX-TP-10000S |

5000ML |

10000ML |

|

|

Two cup mixer (rotation and revolution speed ratio, 10~100 adjustable) |

TMAX-TP-300SS |

150ML |

300ML |

|

TMAX-TP-900SS |

540ML |

1080ML |

|

|

TMAX-TP-1500SS |

1000ML |

2000ML |

|

|

The above capacity is the capacity when the cup is placed in the machine and the material is 5mm away from the cup mouth Selection is mainly to see whether the maximum mixing capacity meets your requirements. We can provide various mixing cup smaller than the machine model to meet the requirements of large machine experiment and small capacity. We also accept custom-made cup and provide suitable fixture accordingly. |

|||

In addition to the standard mixing cup, the machine can also customize fixtures for customers to use their own containers.

Syringe clamp

Disposable cup clamp

Fixtures for customer’s cup

Function extension: ball milling (customized)

In order to meet the multi-function function of one machine for laboratory customers, we extend the ball milling function. Our machine speed is much higher than the traditional Planetary Laboratory ball mill. It has high efficiency and full cavity vacuum to prevent oxidation of materials and air during ball milling. Specific requirements to negotiate configuration, can be equipped with PTFE cup, alumina cup, stainless steel cup.

Teflon Cup:

Stainless steel cup

Alumina cup

Applications

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915