- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

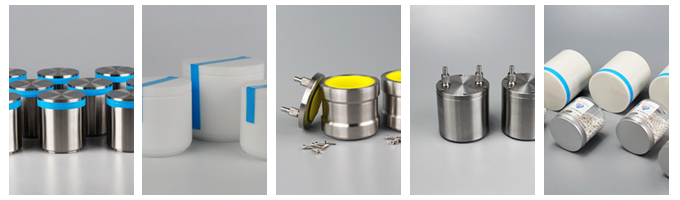

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

Cryogenic Planetary Ball Mill Machine With 4 Jars

Model Number:

TMAX-BallMill-80Type:

Cryogenic Ball MillDimension(L*W*H):

800*470*560 mmNet Weight:

120KGCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

Cryogenic Planetary Ball Mill Machine With 4 Jars

The planetary ball mill is composed of planetary ball mill and cold-air device. Cycling of cold air quickly

takes away the heat generated by grinding by means of air conditioning refrigeration principle, and temperature

inside the grinding space can be controlled at 2-12 °C according to temperature difference of working

environment. Cryogenic planetary ball mill is mainly applied to ultrafine grinding under condition of low

temperature requested by materials.Compared with the artificial injection of liquid nitrogen cooling, cold-air

planetary ball mill is much easier and more convenient to be operated, it is also cost-saved, and low-energy

consumed. Such a cold-air device can be also applied to assembly other models like vertical ball mill,

horizontal ball mill, 360 degree ball mill and dual ball mill.

|

Type No. |

Dimension(mm) |

Max Rotation Speed(rpm) |

Power(kw) |

|

BALLMILL-0.4 |

600*470*730 |

670 |

0.75 |

|

BALLMILL-1 |

600*470*730 |

670 |

0.75 |

|

BALLMILL-2 |

600*470*730 |

670 |

0.75 |

|

BALLMILL-4 |

600*470*730 |

670 |

0.75 |

|

BALLMILL-6 |

1000*730*810 |

670 |

0.75 |

|

BALLMILL-8 |

1000*570*700 |

580 |

1.5 |

|

BALLMILL-10 |

1000*570*700 |

580 |

1.5 |

|

BALLMILL-12 |

1000*570*700 |

580 |

1.5 |

|

BALLMILL-16 |

1260*640*780 |

480 |

3 |

|

BALLMILL-20 |

1500*700*850 |

430 |

4 |

|

BALLMILL-40 |

1500*770*900 |

430 |

5.5 |

|

BALLMILL-60 |

1500*900*1020 |

420 |

7.5 |

|

BALLMILL-80 |

1750*990*1130 |

420 |

11 |

Material Data for Grinding Jars/Balls

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915