- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

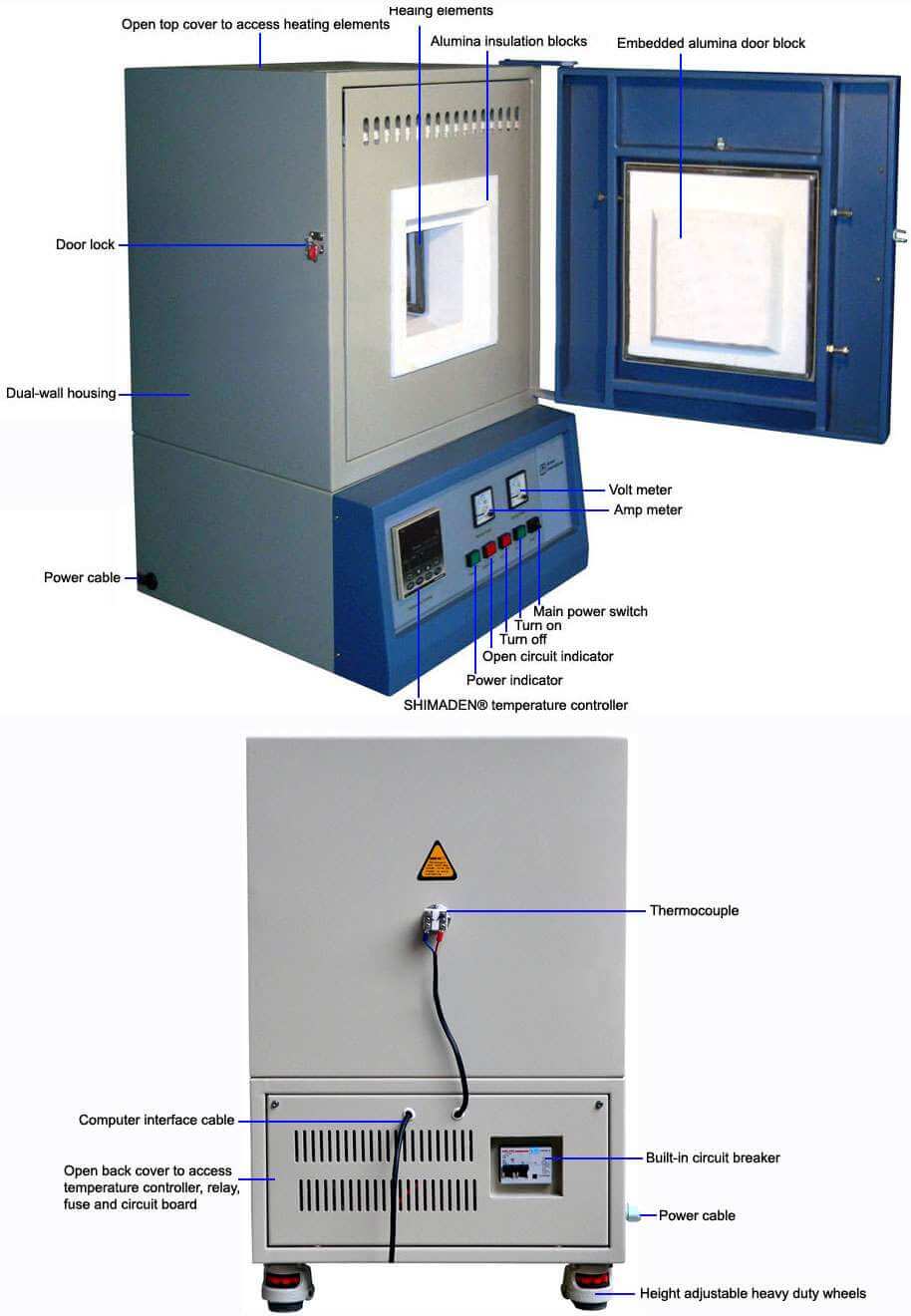

1750°C Muffle Furnace Heat Treatment for Laboratory Equitment

Model Number:

TMAX-1750DDCompliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

1750°C Muffle Furnace Heat Treatment for Laboratory Equitment

Muffle furnace Structure:

High purity alumina fiber insulation surrounding the chamber provides maximum energy efficiency.Heavy duty double layer structure with cooling fan to keep furnace exteriors safe to touch.

Doble layer sreel case with forced air cooling to ensure lower saferface temperature.

One optional venting port is built on the top of furnace,need at extra cost .

Muffle furance details specification:

|

Item No. |

TMAX-1750DD |

|

Chamber size: |

100x100x100 mm, Capacity: 1 liter. |

|

Power: |

2000 W Max. ( power cord is included ) |

|

Voltage: |

AC 220V 50/60 Hz; |

|

Max. Temperature : |

1800 °C for short time ; |

|

Continuous Working Temperature: |

1750 °C Max. ; |

|

Max. Heating Rate: |

0-30 °C /min,Suggest to be 10.C/min. |

|

Temperature Controller : |

PID automatic control and auto-tune function. |

|

Temperature Accuracy : |

+/- 1 °C |

|

Heating Elements : |

MoSi2 heater. |

|

Thermocouple : |

B type |

|

Standard parts: |

crucible tongs 1pc,high temperature gloves 1 pair,one user manual. |

|

Optional parts: |

PLC touch screen controller, paperless recorder,Remote communication control system, observation window, Gas inlet and venting port are installed for using at oxygen or inert gas atmospheres. |

Muffle furnace Standard Sizes:

|

Type |

Furnace size: |

Working/Max.temperature |

Delivery time |

|

1800.C muffle furnace |

100x100x100mm |

1750.C/1800.C |

1-30 days |

|

1800.C muffle furnace |

200x150x150mm |

1750.C/1800.C |

1-30 days |

|

1800.C muffle furnace |

300x200x200mm |

1750.C/1800.C |

1-30 days |

|

1800.C muffle furnace |

400x300x300mm |

1750.C/1800.C |

1-30 days |

Warranty: Two years limited warranty with lifetime support, excluding heating element and ceramic tube damaged by user.

Standard Package

|

Part description |

Quantity |

|

muffle furnace |

1 pc |

|

Type S thermocouple |

1 pc |

|

Stainless steel tongs |

1 pc |

|

Spare heating element |

2 pcs |

|

Alumina thermal cushion block |

1 pc |

|

Thermal gloves |

1 pair |

|

Spare fuse |

2 pcs |

|

USB/RS485 computer interface kit |

1 set |

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915