- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

1700°C Max High Temperature Controlled Atmosphere Box Muffle Furnace w/ PC Interface

Model Number:

TMAX-1700CAtmosphereCompliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

1700°C Max High Temperature Controlled Atmosphere Box Muffle Furnace w/ PC Interface

TMAX-1700°C Atmospheres series controlled atmosphere furnaces feature a chamber with Mitsubishi (Japan) high quality alumina fiber insulation and MoSi2 heating elements. A double walled steel internal housing helps minimize heat loss to exterior surface. Furnace operation is controlled by Shimaden (Japan) 40-segment digital controller with built-in RS485 digital communications port and USB adaptor, allowing the user to connect to a PC for remote control and monitoring of the furnace. You can also save or export test results. All our furnaces are CE compliant.

The benefits of an controlled atmosphere furnace

An atmosphere furnace provides the perfect environment for various procedures in many laboratories, providing the controlled temperature and atmosphere specific projects require. The controlled atmosphere is desired to complete tasks that require exact temperatures with no room for error. This is the best way to ensure the successful outcome of your project because it is sealed tightly to ensure the proper environment.Gases

One of the main components of the atmosphere furnace is the correct mixture of gases. The precise measurement of each gas is essential to the success of your project. You can use a separate chamber to mix the gases, which are then pumped into the furnace chamber where the work will be completed when they are done mixing. It is essential that the separate chamber that holds the gases does not receive any outside air because it could throw off the gas mixture and render your project useless.

Temperature

Proper temperature control is vital to the success of your project as well. Temperatures that are too high or too low will cause problems with the process and could cost your company a significant amount of money. Across International furnaces come with built-in 28-segment PID digital temperature controller for accurate monitoring and consistency.

Features

· Multiple gas inlets and outlets with stainless steel ball valves. Flow meter to control inbound and outbound gas flows. Outlets can be ignited to burn off gas.

· Furnace chamber is welded and oil leak tested to ensure air tightness. Furnace door is sealed with high temperature silicon gasket.

· Built-in stainless steel water-cooling panel protects door sealing gasket when furnace is under heavy use.

· Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

· Multiple atmosphere processes in a single cycle are possible (ex: binder burn out in air and parts sintering under rough vacuum or inert gas environment.)

· Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

· Built-in computer interface.

· CE compliant

Safety

· Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller's manual) or when the thermocouple is broken or malfunctions.

· Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

* Ultimate vacuum level for GCF furnaces is around 100 Pa with all flange connections, and 1000 Pa with hose barb connections. Please keep in mind that our GCF atmosphere furnaces are NOT designed to be vacuum furnaces, the vacuuming part is mainly for users to pre-vac the chamber, before putting in inert or other protective gases.

Specifications

|

Electrical requirements |

208-240V, 50/60Hz, single phase |

|

Heating element type |

Molybdenum silicide (MoSi2, diameter 7mm) |

|

Temperature control |

Controller: Shimaden fp93

(Japan) with 4 programs and 40 segments (ie. 4 x 10 segments or 2 x 20

segments). |

|

Furnace cavity |

Mitsubishi (Japan) high quality grade 1800 morgan polycrystalline alumina fiber |

|

Thermocouple type |

B |

|

Inlet/outlet |

1/4" hose barb with 1/4" BSPT (British Standard Pipe Thread) |

|

Positive pressure |

Not to exceed 0.02 MPa / 150 torr / 3 psi |

|

Download |

Maximum temperatures

|

Air, Nitrogen Dioxide (NO2), Carbon Dioxide (CO2) |

1700°C |

|

Helium (He), Neon (Ne), Argon (Ar) |

1650°C |

|

Sulfur Dioxide (SO2) |

1600°C |

|

Nitrogen (N2), Carbon Monoxide (CO), Hydrogen (H2) up to 5% |

1500°C |

Size comparison

|

Chamber size (DxWxH) |

6x6x6" |

12x8x8" |

16x12x12" |

|

Usable chamber space (DxWxH) |

4x5x5.5" |

10x7x7.5" |

14x11x11.5" |

|

Chamber capacity (cu ft) |

0.13 |

0.44 |

1.33 |

|

Installed heating element |

4 |

8 |

10 |

|

Maximum output |

3 kW |

7 kW |

13 kW |

|

Unit/shipping dimensions (DxWxH) |

30x24x45" / 33x30x51" |

31x26x50" / 37x31x55" |

34x29x60" / 40x36x70" |

|

Unit/shipping weight (Lb) |

430/510 |

620/720 |

880/1050 |

Standard Package

|

Part description |

Quantity

|

Part image |

|

controlled atmosphere furnace

|

1 pc |

|

|

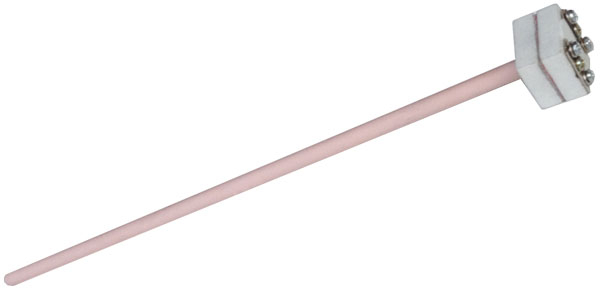

Type K thermocouple

|

1 pc |

|

|

Flow meter

|

1 pc |

|

|

Alumina cushion block |

1 pc |

|

|

Furnace door block |

1 pc |

|

|

Stainless steel tongs

|

1 pc |

|

|

Thermal gloves |

1 pair |

|

|

Spare fuse |

2 pcs |

|

|

USB/RS485 computer interface kit |

1 set |

|

|

Water pump |

1 pc |

|

|

Furnace operation manual |

1 pc |

|

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915