- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

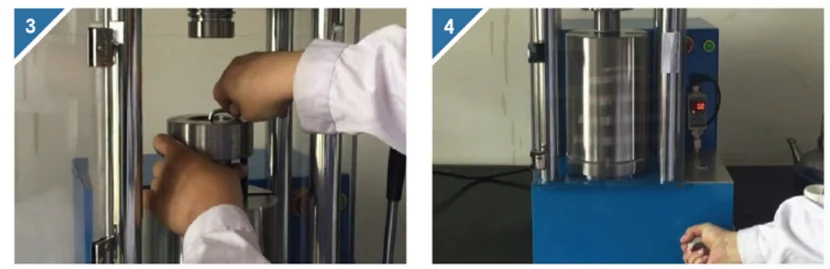

12T Lab Manual CIP (Cold Isostatic Pressing) Press machine with ID 22mm Stainless Steel Tank upto Max.300 Mpa

Model Number:

TMAX-CIP-12JDimension(L*W*H):

305*195*530mmNet Weight:

About 90kgCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

12T Lab Manual CIP (Cold Isostatic Pressing) Press machine with ID 22mm Stainless Steel Tank upto Max.300 Mpa

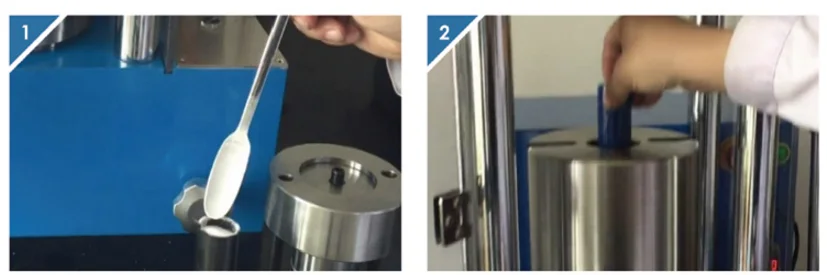

TMAX-CIP-12J is a CE Certified and the smallest cold isostatic pressing (CIP) machine used for laboratory powder pressing. It has a 22mm ID hydraulic chamber made by ultra strength stainless steel, which can provide isostatic pressure up to 300 Mpa via a 12T hydraulic press. It is an excellent tool to prepare high-density compound pellet and small diameter rod. CIP-12J has the small footprint and can be placed in glove-box to prepare air-sensitive materials. A plastic protection cover is included.

12T cold isostatic Pressing machine |

|

|

Application |

Laboratory CIP Pressing |

|

Hydraulic pressing range |

0~12T(0-17MPa) |

|

Piston Diameter |

O.D95mm |

|

Structure |

oil tank,machine base No sealing connection, no oil leak point |

|

Pressure gauge |

Digital pressure gauge |

|

Maximum piston distance |

40mm |

|

Environment temperature |

10~40 degree |

|

CIP Pressure range |

0~300MPa |

|

CIP Tank dimension |

O.D22*70mm |

|

Outer dimension |

305*195*530mm |

|

Gross Weight |

90Kg |

Pressure conversion

|

Real Pressure |

System Pressure |

Tank inner pressure |

|

1T |

1.41MPa |

25MPa |

|

2T |

2.82MPa |

50MPa |

|

3T |

4.23MPa |

75MPa |

|

4T |

5.64MPa |

100MPa |

|

5T |

7.06MPa |

125MPa |

|

6T |

8.46MPa |

150MPa |

|

8T |

11.3MPa |

200MPa |

|

10T |

14.1MPa |

250MPa |

|

12T |

17MPa |

300MPa |

Main Features

a).Small size, light weight,No oil, easy to carry.

b).High speed steel imported from Japan

c).Digital display pressure gauge 0.1MPa,Pressure control is more accurate.

d).The oil pool is easy to replace oil on the main surface of the host, and the

hydraulic oil filter is added to the oil path.

e).Special plunger, special custom sealed structure, good sealing effect, no

oil leakage

f).The upper plate adopts six angle screws in electroplating sunk head. It is

beautiful and saves space.

g).One one main plate structure, oil pool, main board, oil cylinder, on one

body, no seal connection.

h).Lengthening spring, the rebound effect is good, not easy to deform, can

realize the oil cylinder 30mm return no deformation.

i).The Aluminum Alloy handwheel, beautiful, practical, durable, not easy to

damage

Machine Parts: Rubber Mold, can be used recycle

Main Features: CIP Stainless steel tank

Machine Parts: Sealing cap

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915