- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Battery Assembly Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Battery Material Tester

- Film Coating Machine

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Lab Furnaces

- Ball Mill

- Hydraulic Press

- Laboratory Equipment

1100ºC UL Standard RTP Furnace With 4" ID Quartz Tube & Digital Vacuum Gauge

Model Number:

TMAX-1200X-RTP-4Compliance:

CE compliantWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Wechat:13506084915

1100ºC UL Standard RTP Furnace With 4" ID Quartz Tube & Digital Vacuum Gauge

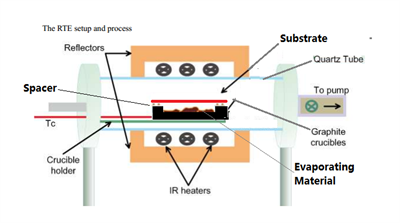

TMAX-1200X-RTP-4 is a compact rapid thermal processing tube furnace with a 4" I.D. processing quartz tube and vacuum flanges. It is designed for annealing semiconductor wafers or solar cells with diameters up to 3". TMAX-1200X-4-RTP is heated by 8 units of 1KW halogen light with a max. the heating rate of 50ºC/second. 30 segment precision temperature controller with +/-1ºC accuracy is built into the furnace to allow for heating, dwelling, and cooling at various steps. RS485 port and control software are included to make monitoring the temperature profile via PC while simultaneously running furnace possible. This furnace also can be modified into an RTE, CSS or HPCVD furnace ( see below application note )

SPECIFICATIONS

|

Furnace Structure |

|

|

Power Input |

208-240 AC, 50/60 Hz single phase, 9 KW Max. (60A breaker required) |

|

|

|

|

Heating Zone |

12" length with 4" constant temperature zone within +/-5ºC uniformity |

|

Working Temperature |

|

|

Max. Heating Rate |

50ºC/sec |

|

Cooling Rate |

|

|

Thermocouple |

K type, the head of the thermocouple touches the Aluminum Nitride sample holder from underneath |

|

Temperature Controller |

|

|

Temperature controller (optional) |

|

|

Quartz Tube & Sample Holder |

|

|

Vacuum Flange |

|

|

Vacuum Pump (optional) |

|

|

Water Cooling (optional) |

|

|

Flow-meter |

One flow meter is installed on the front panel for adjusting gas flow from 16 - 160 ml/min |

|

Vacuum Gauge |

Digital vacuum gauge with a measurement range from 10-4 to 1000 Torr is installed on the furnace. |

|

Vacuum Pressure & Gas Fitting |

|

|

Dimensions |

|

|

Net Weight |

70 kg (150 lbs) |

|

Warranty |

Two years limited manufacturer warranty with lifetime support (Consumable parts such as processing tubes, o-rings and halogen lamps are not covered by the warranty, please order replacements at related products below). |

|

Laptop, software & WiFi Control(Optional) |

|

|

Compliance

|

Please select the certificate in options bar:

CE Certificate & UL/CSA ready: CE approval, ready to pass UL/CSA certificate UL certircate - UL apprval (UL 61010), at extra cost |

|

Optional

|

|

|

ru

ru

cindy@tmaxcn.com

cindy@tmaxcn.com David@battery-equipments.com

David@battery-equipments.com Wechat:13506084915

Wechat:13506084915